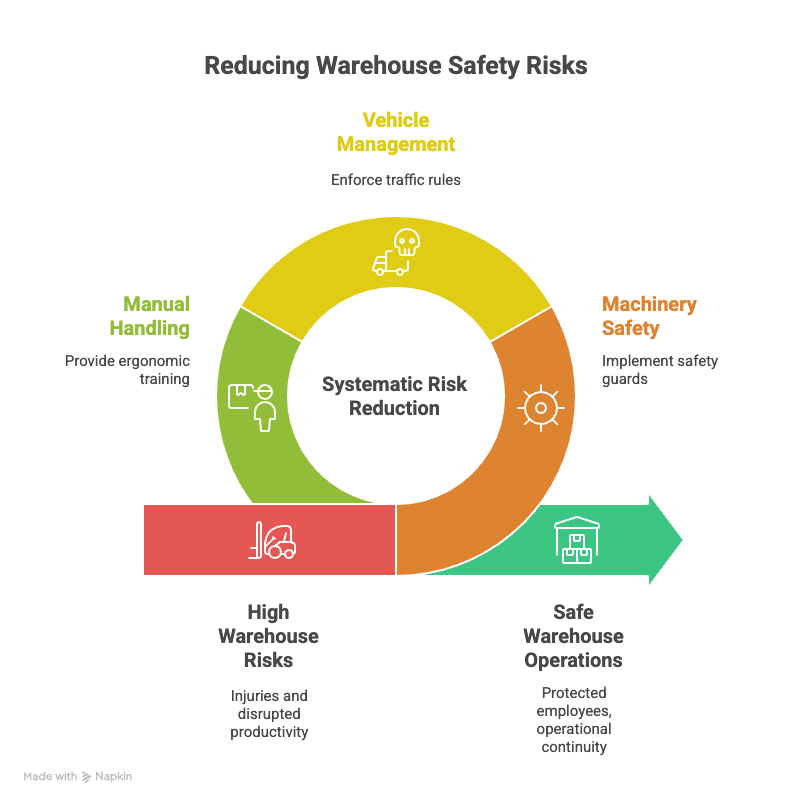

Warehouse operations are central to modern supply chains, but they also present significant safety challenges. Incidents involving machinery, moving vehicles, and manual handling can lead to injuries and disrupt productivity. A systematic approach to risk reduction is essential for protecting employees and maintaining operational continuity.

Proactive Hazard Identification

The first step toward a safer warehouse is identifying potential dangers before they result in an incident. This requires a continuous cycle of observation and analysis. A comprehensive strategy moves beyond simple compliance checks to create a genuinely preventative environment.

Establishing Regular Safety Audits

Scheduled inspections of all work areas help uncover physical hazards like blocked exits, poor lighting, or improperly stored materials. These audits should be thorough and documented, creating a clear path for corrective actions. Performing these checks consistently helps catch issues before they escalate into accidents.

Encouraging Employee Participation

Frontline workers have direct exposure to daily operational risks. Creating simple channels for them to report concerns without fear of reprisal provides invaluable insight. Their feedback can highlight issues that formal audits might miss, leading to a more collaborative and effective safety program.

Optimizing Layout and Traffic Flow

The physical design of a warehouse directly influences safety outcomes. Congested aisles and chaotic interactions between pedestrians and vehicles increase the likelihood of accidents. Careful planning of the workspace is a fundamental aspect of risk management.

Designate clear, well-marked pedestrian walkways separate from vehicle routes.

Implement a one-way system for vehicle traffic to reduce the chance of head-on encounters.

Ensure intersections and blind corners have mirrors or warning signals to improve visibility.

Keep aisles and staging areas free from clutter and obstructions that could cause trips or falls.

Strengthening Safety Culture Through Training

Well-trained employees are better equipped to recognize hazards and follow safe operating procedures. Training should not be a one-time event but an ongoing process that reinforces best practices and adapts to new challenges. Continuous education is important for keeping all team members aware of safety protocols.

Comprehensive Onboarding for New Staff

New hires need specific instruction on the risks associated with their tasks, including proper manual handling techniques and safe operation of equipment. This initial training sets the foundation for their long-term safety performance and ensures they understand their responsibilities from day one.

Continuous Reinforcement and Drills

Regular refresher sessions and practical drills keep safety principles top of mind. These activities can simulate emergency situations, ensuring workers know how to respond correctly. Discussing near-miss events as a team can also be a powerful learning tool that prevents future incidents.

Adopting Modern Safety Technologies

Advances in technology offer new ways to monitor warehouse environments and prevent incidents in real time. These systems can supplement human observation, providing continuous oversight in busy and complex settings. They can identify unsafe behaviors or hazardous situations automatically, allowing for immediate intervention. This proactive monitoring helps organizations move from reacting to incidents to preventing them altogether.

Creating a safer warehouse environment requires a multi-layered approach that combines diligent processes, a well-designed workspace, and a strong safety culture. Organizations can improve their risk management programs and protect their people with the right strategies. For those looking to enhance their operational safety, a modern supply chain safety solution provides the tools needed to identify and address hazards proactively.