Table of Contents

Discover the key advantages and benefits of SKU Rationalization in supply chain management. Learn how this strategic process can streamline inventory, reduce costs, and enhance profitability for your business.

In the ever-evolving international of supply chain control, companies are constantly looking for ways to optimize their operations, lessen prices, and beautify usual efficiency. One of the important thing strategies that has emerged as a game-changer in this realm is SKU clarification. In this text, we’ll delve into the intricacies of SKU clarification, examine its advantages, and offer you complete information on the way it can revolutionize your delivery chain.

What Is SKU Rationalization?

SKU rationalization, or Stock Keeping Unit rationalization, is a process that involves the systematic review and optimization of a company’s product offerings. It aims to streamline the product catalog by identifying and eliminating underperforming, redundant, or low-margin items. The ultimate goal is to simplify inventory management, reduce carrying costs, and enhance profitability.

The SKU Rationalization Formula

At the core of SKU rationalization lies a formula that combines data analysis and strategic decision-making.

1. Data Collection

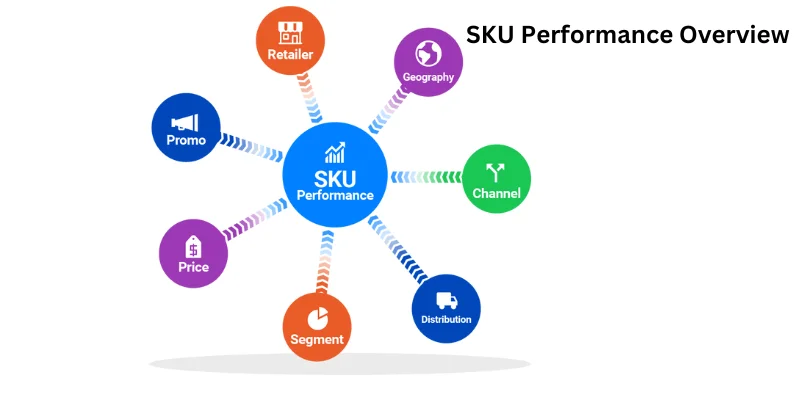

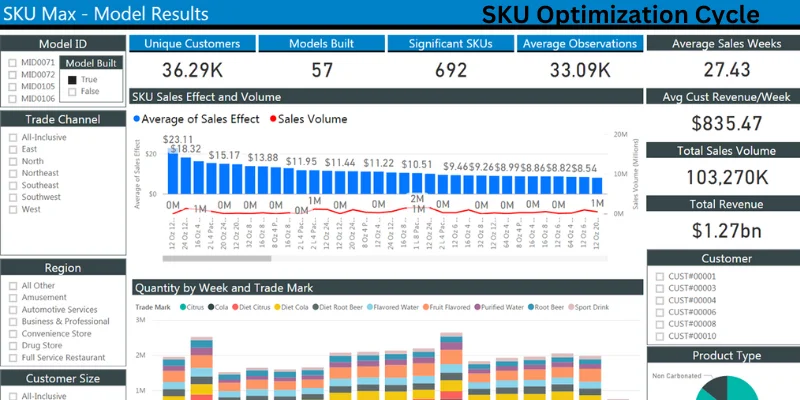

To initiate SKU rationalization, a comprehensive data collection process is essential. This involves gathering data on sales performance, demand trends, product profitability, and other relevant metrics. Modern supply chain management tools and software can significantly ease this data collection process.

2. Performance Analysis

Once the data is collected, it’s time to analyze the performance of each SKU. Factors to consider include sales volume, revenue, profit margins, and carrying costs. Products that consistently underperform or have a negligible impact on the bottom line are identified for potential removal.

3. Categorization

SKUs are categorized based on their performance. Categories typically include:

- Core Products: High-performing items that are essential to the company’s success.

- Supporting Products: Items that complement core products but may not be as profitable individually.

- Non-Essential Products: Low-performing items that contribute minimally to overall revenue.

4. Decision-Making

This is where strategic decisions come into play. Businesses must decide whether to keep, modify, or discontinue each SKU based on the data analysis and categorization. This step requires a keen understanding of the company’s overall goals and a commitment to optimizing the product catalog.

5. Implementation

Once decisions are made, it’s time to implement the changes. This may involve discontinuing low-performing SKUs, modifying marketing strategies for certain products, or reallocating resources to focus on core products.

SKU rationalization process into a step-by-step guide:

Step 1: Data Collection

- Start by gathering comprehensive data on all your products. This includes sales data, demand patterns, profit margins, and carrying costs. Modern inventory management software and tools can be immensely helpful in this phase.

Step 2: Performance Analysis

- Analyze the collected data to evaluate the performance of each SKU. Key performance indicators to consider include sales volume, revenue generated, profit margins, and carrying costs. Identify which products consistently underperform or have a limited impact on profitability.

Step 3: Categorization

- Categorize your SKUs based on their performance. This typically involves classifying them into three categories:

- Core Products: These are high-performing, essential items crucial to your company’s success.

- Supporting Products: These products may not be as profitable individually but complement core products.

- Non-Essential Products: Low-performing items that contribute minimally to overall revenue.

Step 4: Decision-Making

- With your SKUs categorized, it’s time to make strategic decisions. Consider whether to keep, modify, or discontinue each SKU. These decisions should align with your overarching business goals and the data-driven insights you’ve gathered.

Step 5: Implementation

- After making decisions, it’s time to put them into action. Implement the changes, which may involve discontinuing low-performing SKUs, optimizing marketing strategies for certain products, or reallocating resources to focus on core products.

Benefits of SKU Rationalization

Now that we have a clear understanding of the process, let’s explore the benefits of SKU rationalization in the supply chain.

1. Cost Reduction

One of the most significant advantages of SKU rationalization is cost reduction. By eliminating underperforming and non-essential SKUs, a business can reduce inventory carrying costs, storage space requirements, and operational complexities.

2. Enhanced Efficiency

With a simplified product catalog, businesses can streamline their operations. Inventory management becomes more straightforward, allowing for quicker order fulfillment and reduced lead times.

3. Improved Profit Margins

Focusing on high-performing products can significantly boost profit margins. By allocating more resources to core products and optimizing pricing strategies, businesses can maximize their revenue potential.

4. Data-Driven Decision-Making

SKU rationalization is a data-driven process. It ensures that decisions are based on empirical evidence rather than assumptions. This data-centric approach leads to more informed and strategic choices.

5. Better Resource Allocation

By reallocating resources from underperforming SKUs to core products, businesses can invest in marketing, product development, and customer service initiatives that truly matter. This targeted allocation of resources can lead to long-term growth and sustainability.

(Stock Keeping Unit) SKU process steps:

| Step | Process Description |

|---|---|

| 1 | Receive Inventory: Accept incoming goods |

| 2 | Unpack and Inspect: Examine the products |

| 3 | Assign SKU: Unique code for each product |

| 4 | Catalog Information: Record product data |

| 5 | Storage: Place items in designated areas |

| 6 | Update Inventory: Adjust stock levels |

| 7 | Pick and Pack: Retrieve and prepare orders |

| 8 | Quality Control: Ensure items meet standards |

| 9 | Shipping: Dispatch orders to customers |

| 10 | Returns Handling: Manage product returns |

| 11 | Inventory Management: Track stock levels |

| 12 | Reorder Stock: Restock low inventory items |

| 13 | Reporting: Generate SKU-related reports |

| 14 | SKU Maintenance: Update SKU information |

Final Thought

In dynamic and aggressive enterprise surroundings, supply chain optimization is paramount. SKU explanation is a powerful device that empowers companies to make informed selections, reduce prices, and enhance profitability. By following the SKU explanation components and reaping its advantages, you could remodel your delivery chain right into a lean, green, and earnings-driven powerhouse.

FAQs

Q1: How do you conduct SKU rationalization?

A1: SKU rationalization involves data collection, performance analysis, categorization, strategic decision-making, and implementation.

Q2: What is an example of SKU rationalization?

A2: An example is a clothing retailer discontinuing low-margin t-shirt variations to streamline inventory and increase profitability.

Q3: What is the 80/20 rule for SKU rationalization?

A3: The 80/20 rule suggests focusing on the top 20% of products that contribute to 80% of sales for optimal results.

Q4: Why is SKU rationalization important?

A4: SKU rationalization simplifies inventory, enhances efficiency, boosts profit margins, and ensures data-driven decision-making for sustainable growth.