Table of Contents

Find out the major value adds and benefits that SKU Rationalization brings to supply chain management. Know how this strategic process is capable of streamlining your inventory, lowering your costs, and increasing the level of profitability within business operations.

Businesses constantly adjust international supply chain control in an ever-evolving manner as they seek varying means to optimize their operations, reduce prices, and better enhance usual efficiency. One of the essential thing strategies that has emerged as a game-changer in this realm is SKU clarification.

This writing shall expound on the complexities of SKU clarification, and discuss its benefits and provide you with detailed information on how it can be the next big thing in your delivery chain.

What Is SKU Rationalization?

SKU rationalization is the strategic process of reviewing and optimizing a company’s inventory. In most cases, SKU rationalization focuses on the stock-keeping unit and product catalog.

The main goal of rationalizing the number of SKUs is to spot underperforming, redundant, or low-margin items and cut the product line so that better turnover can be achieved as well as reduced carrying costs. Some other direct advantages of SKU rationalization include improved profits, better optimization in inventory management, and easier inventory cost tracking.

As firms trim down their product lists, they also do a cleanup drive becoming more and more operationally efficient by reducing SKUs in the lineup and eliminating flab.

SKU rationalization is not simply a process of SKU reduction. It involves the entire product portfolio with an eye on both customer satisfaction and supplier management. Such a process allows companies to manage their product mix effectively by discontinuing items that do not contribute positively to the bottom line.

SKU rationalization enables firms to concentrate more on those products that have a higher propensity to perform well in the market yet at the same time are able to fulfill customer demands. Firms offer a wide assortment of product mixes with reduced SKUs that would streamline the supply chain as well as reduce storage costs.

The SKU Rationalization Formula

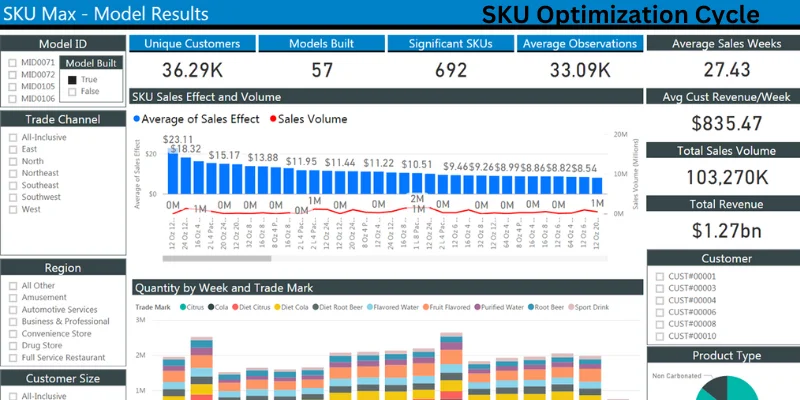

SKU rationalization is driven by a mixture of data analysis and strategy formulation that sits at the center of this process to optimize inventory. The performance of SKUs is evaluated on the basis of their sales, inventory turnover rate, and profitability so that it can be decided by the company whether that product should be kept in stock or not.

This equation also factors in stock administration applications and prognostication instruments to anticipate forthcoming interest and improve SKU methodology. By assessing SKU information, organizations gain knowledge of each item’s life cycle which helps decide the product mix that will bring about maximum profit.

1. Data Collection

SKU rationalization begins with a comprehensive data collection exercise, initiated by an SKU analysis, sales data, and current inventory levels. A review of inventory turnover, holding costs, and customer satisfaction will assist the business in determining which products are performing well and which might be on the chopping block.

Information about every SKU, right from particular SKU codes to SKU counts assists in managing the warehouse as well as keeping it optimized to the level required for operational efficiency.

The management process involves reviewing the SKU proliferation in the product catalog so as to mitigate holding costs brought about by slow-moving stocks. Through rationalization of SKUs as a strategy, firms can respond to the issue on SKU proliferation, enhancing their stock availability while ensuring that every single SKU has multiple advantages.

The SKU rationalization strategy, hence involves an evaluation of how each product contributes to profitability and what role it plays in the whole lineup. Therefore, the formula for SKU rationalization is basically a way to understand how changes made to your product line can affect both the lifecycle management of products and supply chains.

2. Performance Analysis

After collection of data, analyze how well each SKU has performed. Some factors that shall be considered include sales volume, revenue, profit margins, and carrying costs. Products that consistently underperform or have negligible impact on the bottom line will be identified for possible removal.

3. Categorization

SKUS are categorized based on their performance. Categories usually include:

- Core Products: high performance items that are essential to the company’s success.

- Supporting Products: Items that complement main products, but may not be so profitable individually.

- Non-Essential Products: low performance items that contribute minimally to general revenue.

4. Decision-Making

This is where strategic decisions are made. Based on the analysis and categorization, whether to keep, modify, or discontinue each SKU is decided by businesses in this phase. It requires a great understanding of the company’s general goals and willingness toward the optimization of the product catalog.

5. Implementation

After decisions come implementation. This could be the discontinuation of low-performing SKUs, changes in marketing strategies for particular products, or just a simple shift back to core products that might require resources.

SKU rationalization process into a step-by-step guide:

Step 1: Data Collection

- Begin with collecting comprehensive data on all your products. That includes sales figures, demand patterns, profit margins, and carrying costs-all of them. Modern inventory management software and tools will prove very handy at this stage.

Step 2: Performance Analysis

- Review the collated information to judge how well each SKU is performing. The major indicators of performance are the quantity sold, money brought in, profit made, and costs held against them. Some products do not perform well most of the time. Others have a low contribution toward making profits.

Step 3: Categorization

- Categorize your skus based on their performance. This usually involves classifying them into three categories:

- Core Products: These are high performance items, crucial to the success of your company.

- Supporting Products: These products may not be so profitable individually, but complement main products.

- Non-Essential Products: low performance items that contribute minimally to general revenue.

Step 4: Decision-Making

- Having made decisions concerning your SKUs, you should now make strategic choices about whether to retain, adjust, or discontinue each SKU. This should be in line with your overall business objectives and the insight intelligence already garnered.

Step 5: Implementation

- Follow through by implementing those decisions. Put into effect whatever changes have to be made-discontinuation of low-performing SKUs, better marketing strategies for some products, or even resource allocation toward core products.

Benefits of SKU Rationalization

The process is now clearly understood, proceeding to the advantages that accrue from rationalization of SKUs in the supply chain.

1. Cost Reduction

Cost reduction happens to be one of the major advantages that accrue from rationalization of SKUs. A company gets to do away with underperforming and non-essential SKUs, thus reducing costs used in carrying extra inventories, storage space required, and even reducing operational complexities.

2. Enhanced Efficiency

A simple product catalog makes everything easy. It is easier to manage stock, hence faster to fulfill orders and lead time is reduced.

3. Improved Profit Margins

High-performing products greatly improve the profit margin. More resources for core products and better pricing strategies unlock the revenue potential of a business.

4. Data-Driven Decision-Making

SKU rationalization is a data-driven process. It ensures that decisions are based on empirical evidence rather than assumptions. This data-centric approach leads to more informed and strategic choices.

5. Better Resource Allocation

Reallocation of resources from underperforming SKUs to core products allows investment in marketing, product development, and customer service initiatives which will count. Targeted allocation of resources results in long-term growth, and sustainability.

(Stock Keeping Unit) SKU process steps:

| Step | Process Description |

|---|---|

| 1 | Receive Inventory: Accept incoming goods |

| 2 | Unpack and Inspect: Examine the products |

| 3 | Assign SKU: Unique code for each product |

| 4 | Catalog Information: Record product data |

| 5 | Storage: Place items in designated areas |

| 6 | Update Inventory: Adjust stock levels |

| 7 | Pick and Pack: Retrieve and prepare orders |

| 8 | Quality Control: Ensure items meet standards |

| 9 | Shipping: Dispatch orders to customers |

| 10 | Returns Handling: Manage product returns |

| 11 | Inventory Management: Track stock levels |

| 12 | Reorder Stock: Restock low inventory items |

| 13 | Reporting: Generate SKU-related reports |

| 14 | SKU Maintenance: Update SKU information |

Final Thought

In dynamic and aggressive enterprise surroundings, supply chain optimization is paramount. SKU explanation is a powerful device that empowers companies to make informed selections, reduce prices, and enhance profitability. By following the SKU explanation components and reaping its advantages, you could remodel your delivery chain right into a lean, green, and earnings-driven powerhouse.

FAQs

Q1: How do you conduct SKU rationalization?

A1: SKU rationalization involves data collection, performance analysis, categorization, strategic decision-making, and implementation.

Q2: What is an example of SKU rationalization?

A2: An example is a clothing retailer discontinuing low-margin t-shirt variations to streamline inventory and increase profitability.

Q3: What is the 80/20 rule for SKU rationalization?

A3: The 80/20 rule suggests focusing on the top 20% of products that contribute to 80% of sales for optimal results.

Q4: Why is SKU rationalization important?

A4: SKU rationalization simplifies inventory, enhances efficiency, boosts profit margins, and ensures data-driven decision-making for sustainable growth.