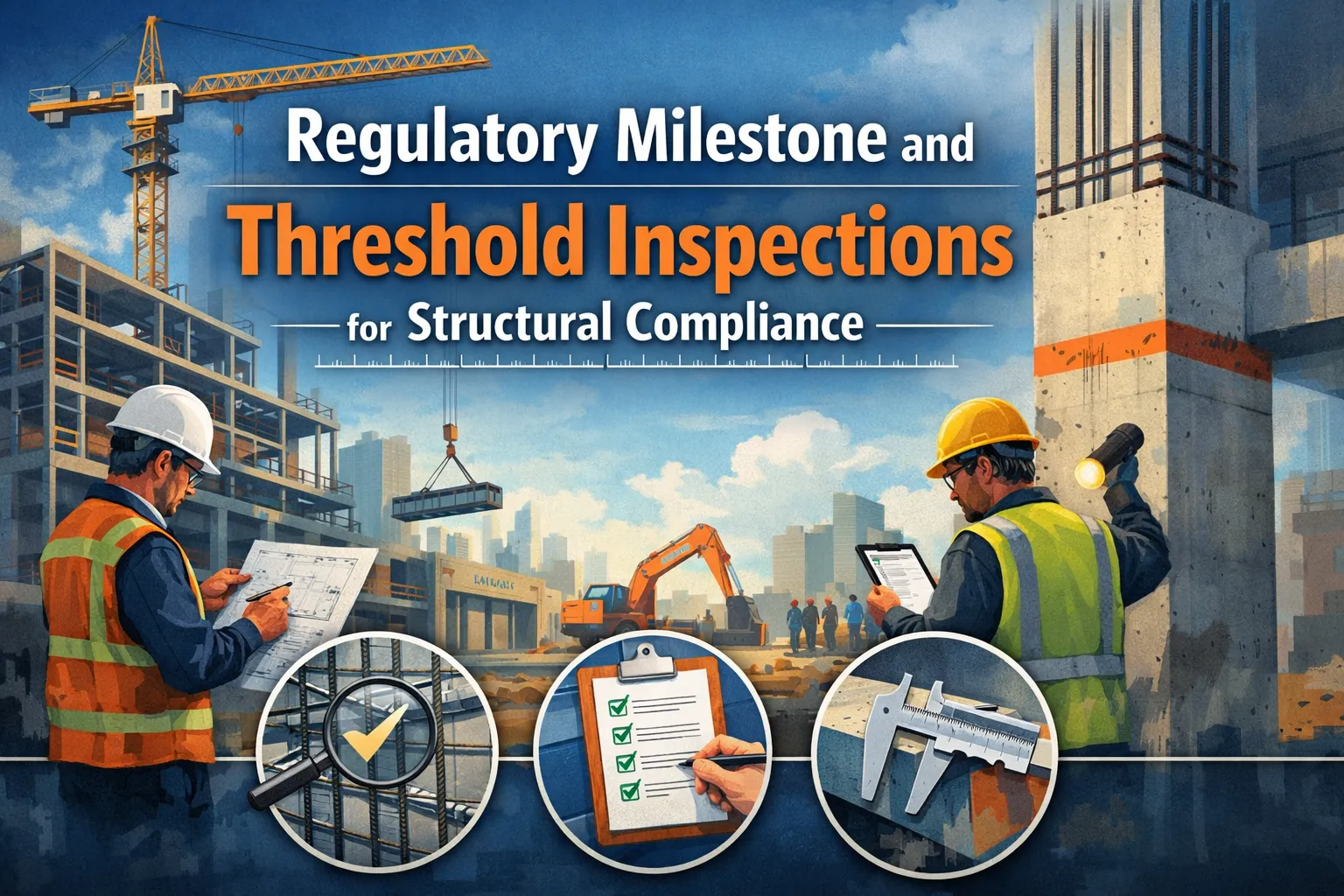

Regulatory Milestone and Threshold Inspections for Structural Compliance

Florida’s updated building safety regulations have significantly increased accountability for property owners, condominium associations, and developers. Milestone and threshold inspections…