Table of Contents

The logistics world is changing fast in the UK, and the choice between 3PL VS 4PL has real consequences for costs, control and strategic growth. In 2025, UK logistics continues to grapple with Brexit-related customs friction, booming E-commerce fulfilment demand and pressing sustainability targets. Outsourcing with third-party or fourth-party logistics partners is no longer optional for many small and medium enterprises (SMEs); it is a strategic choice to stay competitive.

UK 3PL market estimates place its size between USD 29.10 billion and USD 38.52 billion in 2025, with projected growth continuing through the end of the decade.

Choosing the right model begins with defining your logistics needs. A 3PL (Third-Party Logistics) provider takes on operations like warehousing, transportation and order fulfilment. A 4PL (Fourth-Party Logistics) partner goes further, coordinating multiple 3PLs and suppliers and managing the entire supply chain.

For UK SMEs with simple distribution and regional markets, 3PL often delivers faster ROI with lower upfront costs. In contrast, 4PL can unlock strategic visibility and optimisation for complex, multi-channel supply chains. This article breaks down both models, compares benefits and costs, and offers practical guidance for the UK SME market as of 26 December 2025.

What is 3PL, and how do UK SMEs benefit

A 3PL partner handles outsourced logistics tasks such as warehousing, fulfilment, parcel shipping and returns processing. 3PLs give SMEs access to infrastructure and expertise without owning assets.

Core features of 3PL

A 3PL service typically includes:

• Warehousing and storage at distributed sites.

• Transportation management and freight forwarding.

• Inventory control and demand fulfilment.

• Value-added services (returns, packaging, pick & pack).

In the UK, ecommerce growth and international trade have driven warehouse demand. There are now more than 98,000 fulfilment warehouses, up 42 % since 2021, with automated robotics and AI frequently used by 3PL operators to raise efficiency.

Key data points (3PL)

| Metric | Value (2025) | Outlook |

|---|---|---|

| UK 3PL market size (USD) | 29.10 billion–38.52 billion | Growing CAGR ~3.9–4.4 % |

| Warehouse fulfilment facilities | 98,000+ | Increasing |

| 3PL satisfaction (shippers) | 95 % positive | Strong relationships (global study) |

SMEs typically choose 3PL to reduce labour costs, speed delivery times and free internal teams to focus on sales and product development. For UK businesses selling across Great Britain and Northern Ireland, 3PL partners handle customs clearance, stock allocation and short-lead regional logistics.

What is 4PL, and why does it make sense

A 4PL provider takes responsibility for your entire supply chain, including technology, supplier networks and multiple external logistics partners. They act as a strategic integrator rather than a simple service provider.

Core features of 4PL

A 4PL typically provides:

• End-to-end supply chain management and optimisation.

• Multi-partner coordination (multiple 3PLs, carriers, tech).

• Real-time analytics and control-tower visibility.

• Continuous process improvement and strategic planning.

This model is often justified when your logistics network spans multiple countries or modes of transport, or where data-driven forecasting and integration deliver meaningful cost savings. Unlike 3PL, a 4PL rarely owns warehouses or trucks; it orchestrates services via partners.

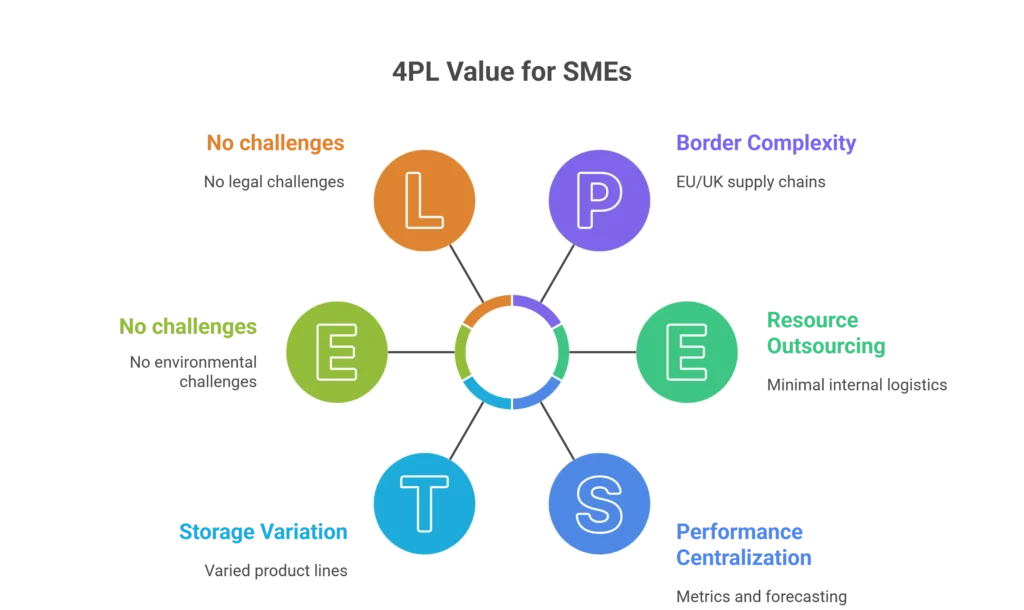

When 4PL becomes valuable for SMEs

• Complex supply chains crossing EU/UK borders.

• Multiple product lines with varied storage conditions.

• Need for centralised performance metrics and forecasting.

• Outsourced logistics strategy with minimal internal resources.

A 4PL becomes most compelling when the cost of coordination and delays outweigh the management overheads an SME would otherwise carry internally.

Head-to-head comparison: 3PL VS 4PL

Choosing between 3PL VS 4PL depends on budget, complexity and growth strategy. Here’s a direct comparison for UK SMEs.

| Aspect | 3PL | 4PL |

|---|---|---|

| Primary role | Operational logistics | Strategic supply chain orchestration |

| Control level | You retain more control | Provider leads decision-making |

| Cost structure | Service fees per function | Management fees and integration costs |

| Best for | SMEs with straightforward fulfilment | Complex, multi-partner logistics |

| Tech use | WMS and tracking | End-to-end analytics & control towers |

3PLs execute day-to-day logistics and can adapt quickly to seasonal SKU shifts. 4PLs integrate analytics and long-term planning, often using advanced dashboards and KPI tracking.

The major distinction is the scope of control: 3PL handles your tasks, 4PL handles your entire logistics ecosystem.

UK regulatory and compliance context

UK SMEs must navigate customs regulations post-Brexit. Duty declarations, import procedures and tariff classifications add complexity to cross-channel logistics. 3PLs often include customs support as part of their service offering, reducing administrative burden. In contrast, 4PLs provide strategic oversight of compliance across suppliers and carriers, helping you avoid delays and fines at ports and terminals.

As of December 2025, UK customs systems continue to adapt, and many SMEs rely on their logistics partners to ensure compliance with HMRC requirements for controlled goods and VAT accounting. Logistics partners with robust compliance teams to reduce regulatory risk and lower administrative costs.

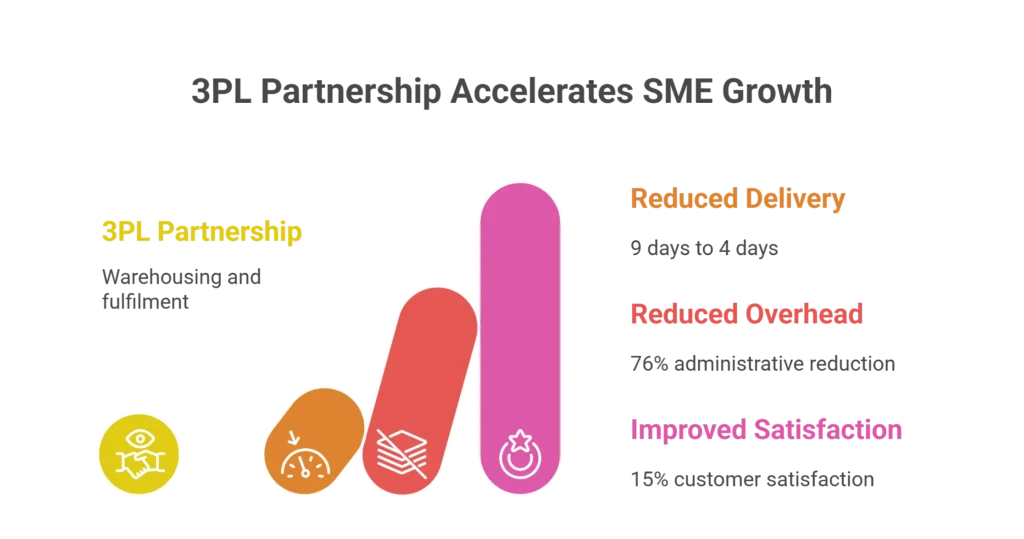

Case Study: A UK fashion SME scales with 3PL

In 2025, a Midlands-based fashion brand expanded from UK-only to European sales. They partnered with a 3PL that provided warehousing in the Midlands and a fulfilment centre near Rotterdam. Utilising real-time inventory feeds and integrated parcel networks, they reduced delivery times to EU customers from 9 days to 4 days within six months. The 3PL also handled Brexit-related customs paperwork, reducing administrative overhead by 76 % and improving customer satisfaction scores by 15 %.

This real example shows how targeted 3PL partnerships can accelerate SME growth in cross-border markets without the high strategic costs of 4PL.

Choosing the right model for your SME

Your choice between 3PL VS 4PL should follow a clear decision flow:

- Assess complexity: Simple regional logistics lean towards 3PL.

- Budget constraints: Upfront cost and transparency favour 3PL.

- Growth ambitions: Multi-node supply chains may benefit from 4PL.

- Tech needs: If you require real-time control and forecasting, 4PL deserves consideration.

Many UK SMEs start with a strong 3PL foundation and adopt elements of 4PL as they scale. A hybrid approach delivers operational efficiency now and strategic orchestration later.

Bottom Line

For most UK SMEs in December 2025, a 3PL model provides a practical and cost-efficient logistics backbone. It handles warehousing, fulfilment and transport without heavy capital investment. However, if your business operates cross-border and requires centralised oversight and optimisation, a 4PL partner can unlock strategic advantages. Analyse your budget, complexity and growth goals carefully. The right logistics model will reduce costs, improve delivery performance and support long-term expansion.

FAQs

What is the main difference between 3PL and 4PL?

3PL executes logistics tasks; 4PL manages the entire supply chain strategy.

Is 4PL more expensive than 3PL?

Typically, yes, due to strategic management and integration fees.

Can SMEs use both 3PL and 4PL?

Yes, hybrid models are common as businesses scale.

Do 3PLs handle UK customs clearance?

Many UK 3PLs include customs support in their services.

Which model improves visibility the most?

4PL usually offers broader end-to-end supply-chain visibility.

Disclaimer

This article is for informational purposes only and does not constitute logistics, legal, or regulatory advice. Businesses should consult professional providers before making decisions.