Table of Contents

Warehousing and Logistics are core functions in global supply chains in 2025, yet many businesses still use the terms interchangeably. Warehousing and Logistics serve different but connected roles that impact inventory management, delivery timelines, and supply chain costs.

Warehousing refers to the physical process of storing and managing goods inside dedicated facilities. Logistics covers the broader planning, movement, coordination, and delivery of goods from origin to destination. Markets highlight these distinctions: the global Warehousing and Storage market is valued at USD 713.06 billion in 2025 and is projected to grow through 2029 at a 7.7% CAGR.

In contrast, the Warehousing and Distribution Logistics market (a combined segment) is forecast to expand by USD 95.2 billion between 2025 and 2029 at a 7.1% CAGR. This growth underscores the rising complexity and integration of warehousing into end-to-end logistics operations.

Understanding the differences between Warehousing and Logistics helps businesses optimize storage costs, reduce delivery delays, and improve customer satisfaction.

Warehousing Defined: Purpose and Function

Warehousing is the operational backbone where goods are received, stored, and prepared for distribution. At its core, warehousing provides space for inventory before products move further in the supply chain. Functions include receiving shipments, quality inspections, organizing inventory, picking, packing, and dispatch.

In today’s market, warehouses do much more than hold stock. They act as active hubs that reduce spoilage, align stock with demand, and support rapid fulfillment. They also optimize handling for e-commerce, retail, and manufacturing sectors where seasonal demand fluctuations are significant. Key functions include consolidation, breakdown of large shipments, inventory accuracy, and efficient order staging.

Data from 2025 highlights that warehousing has evolved into a strategic asset, not just a storage location. Companies now embed automated systems, sensor-based inventory tracking, and real-time analytics to manage throughput and accuracy. Effective warehousing improves order accuracy and response times while ensuring products are ready when logistics systems schedule transport.

Logistics Explained: Strategy and Movement

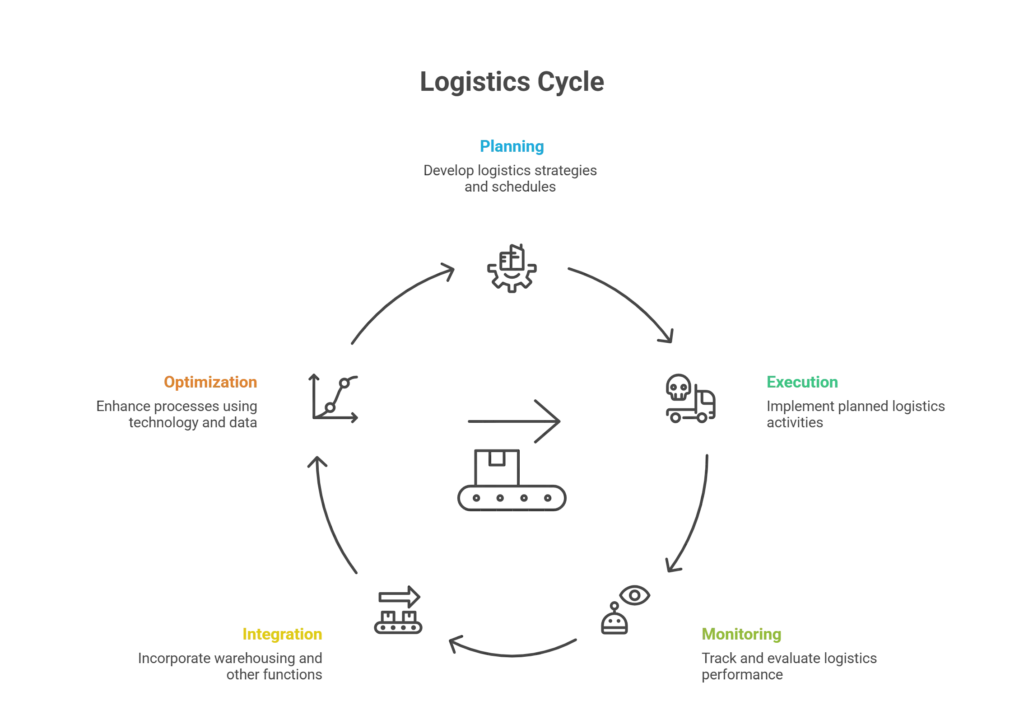

Logistics is the planning, execution, and monitoring of goods movement across the supply chain. This includes inbound and outbound transportation, route planning, carrier management, customs clearance, and delivery scheduling. Logistics integrates warehousing as one of its functional components.

In 2025, logistics is shaped by advanced technologies such as AI, IoT, and blockchain systems that improve forecasting, routing, and real-time tracking. Industry trends show that logistics providers increasingly adopt digital platforms to reduce transportation costs, improve on-time delivery, and enhance transparency for customers.

Logistics also involves demand forecasting and inventory planning. Efficient logistics systems minimize lead times and costs while improving service quality. In contrast to warehousing, which focuses on physical storage, logistics optimizes processes across the entire supply chain. Planning decisions, carrier performance data, and transportation cost benchmarks are central to logistics management.

Key Differences Between Warehousing and Logistics

| Aspect | Warehousing | Logistics |

|---|---|---|

| Primary Focus | Storage and inventory staging | Transport, routing, and carrier coordination |

| Scope | Facility-centric | End-to-end supply chain |

| Core Activities | Receiving, storing, picking, packing | Transport, routing, carrier coordination |

| Performance Metrics | Inventory accuracy, space utilization | Delivery speed, transportation costs |

| Role in Supply Chain | Supports distribution readiness | Drives overall supply chain efficiency |

This table highlights that warehousing targets inventory readiness and physical handling, while logistics optimizes movement and timing across markets and geographies.

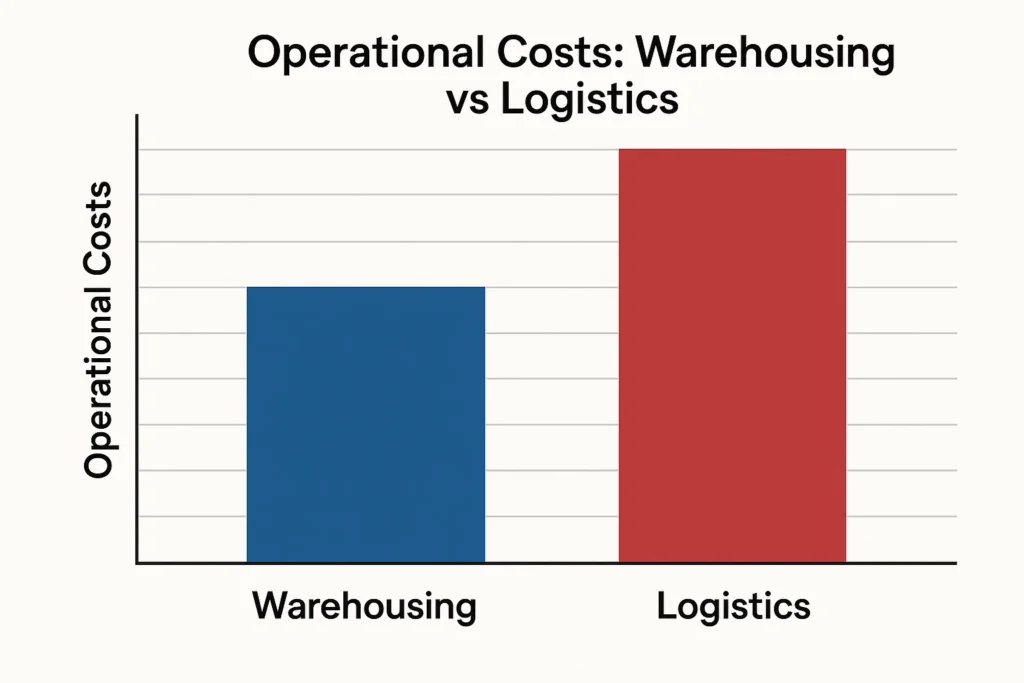

Operational Costs: Warehousing vs Logistics

Warehousing and Logistics each carry unique cost components. Warehousing expenses include facility leasing, labor, shelving and racking systems, energy for temperature-controlled storage, and technology investments. Distribution costs, which form a part of logistics, include fuel, driver wages, vehicle maintenance, tolls, and freight charges.

In modern supply chains, cost optimization strategies vary by segment. For example, efficient warehousing systems use automation to reduce order processing times and shrink labor costs. Logistics cost management uses route optimization and consolidated transportation to lower fuel and carrier fees. While warehousing focuses on internal process efficiency, logistics cost initiatives span across sites and transport modes.

Because logistics encompasses warehousing as part of its broader scope, organizations that improve warehouse throughput often see direct savings in transportation costs. Investment in warehouse technology can reduce dwell time and support faster shipments.

Market Growth and Industry Trends

The warehousing and storage industry in 2025 is large and expanding. The global warehousing and storage market reached USD 713.06 billion and is forecast to grow to USD 960.2 billion by 2029 at a CAGR of 7.7%. Growth reflects rising e-commerce demand, omni-channel distribution, and global trade complexity.

Meanwhile, the warehousing and distribution logistics segment itself is set to grow by USD 95.2 billion from 2025 to 2029 with a 7.1% CAGR, signaling stronger integration between warehousing and logistics services.

Trends show increasing automation in warehouses, real-time tracking in logistics, and greater use of predictive analytics to balance stock levels and delivery performance. These shifts narrow the gap between warehousing and logistics, yet the core roles remain distinct.

Technology’s Role in Differentiation

Warehousing in 2025 uses warehouse management systems (WMS), automated storage and retrieval systems (ASRS), and robotics to improve inventory accuracy and reduce cycle times. Visibility platforms enable managers to see stock levels in real-time.

Logistics adopts broader digital transformation tools like AI-driven route planning, IoT sensors for shipment tracking, blockchain for secure documentation, and machine learning to improve forecasts. These tools provide end-to-end insights from warehouse doors to final delivery.

The differing adoption patterns reflect each function’s goals. Warehousing technologies target efficiency within facilities. Logistics tools focus on connectivity across multiple facilities and transport modes.

Functional Overlap and Integration

While concepts differ, warehousing and logistics must integrate for supply chains to succeed. Warehousing provides ready stock at the right time. Logistics ensures those goods reach customers swiftly and cost-effectively. Reports show that well-integrated warehousing and logistics systems reduce stockouts and lower total freight and handling costs.

Without seamless integration, companies risk delays, higher expenses, and damaged customer experiences. Strategic alignment of warehousing and logistics planning leads to improved delivery predictability and inventory optimization for businesses of all sizes.

Bottom Line

Understanding the distinction between Warehousing and Logistics is essential for supply chain success in 2025. Warehousing provides secure, organized storage and prepares goods for shipment. Logistics plans and executes the efficient movement of those goods across networks. Clear separation of roles enables better cost allocation, performance measurement, and technology investment.

As markets grow and customer expectations rise, businesses that align warehousing operations with logistics strategies will unlock faster delivery, higher accuracy, and stronger competitive positioning. Integrating data, automation, and end-to-end visibility delivers measurable improvements in both functions. For modern supply chains, the synergy between Warehousing and Logistics is not optional; it’s operationally essential.

Disclaimer:

The information in this article is provided for general educational purposes only. While we strive for accuracy and up-to-date data, logistics markets and industry conditions can change quickly.