Table of Contents

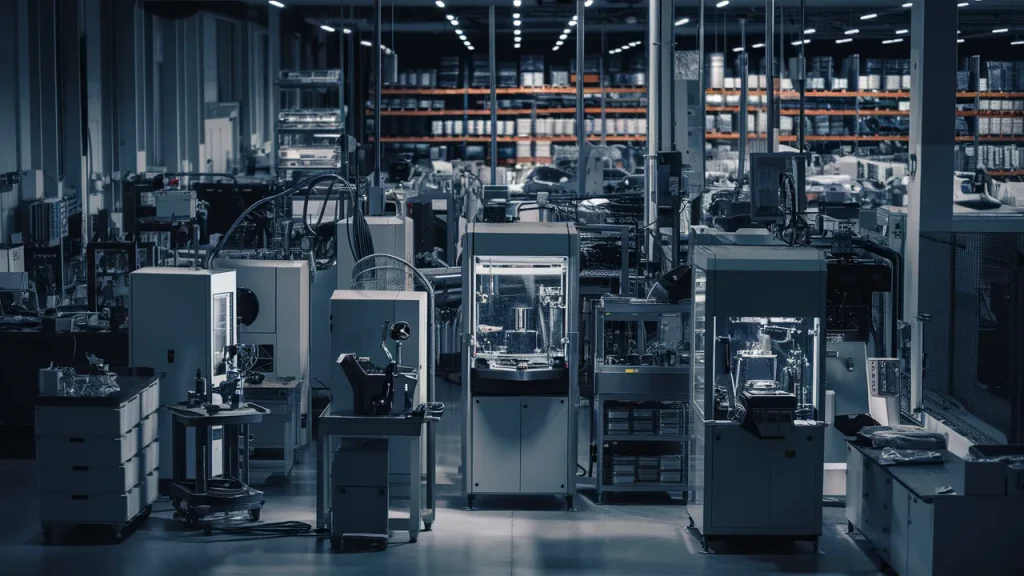

Warehouse equipment is significant in making your business run smoothly by providing effective warehouse solutions.

The right tools can help you work faster, safer, and save money. Let’s explore the world of warehouse equipment and how it can improve your operations.

What is Warehouse Equipment?

Warehouse equipment, both new and used, includes all the tools and machines used to store, move, and manage goods effectively in warehouse operations.

This can be simple things like shelves or complex machines that move items automatically. Good warehouse equipment helps you keep track of your stock, move things quickly, and keep your workers safe.

Types of Warehouse Equipment

Storage Equipment

Storage equipment helps you keep your goods organized and easy to find. Some common types are:

- Pallet Racks: These are metal frames that hold pallets of goods. They let you stack items high, saving floor space.

- Shelving Units: These are great for smaller items or boxes. You can adjust the shelves to fit different sizes of goods.

- Bins and Containers: These are perfect for small parts or items. They keep things tidy and easy to find.

- Mezzanines: These are like extra floors in your warehouse, enhancing your facility’s storage capacity. They help you use all the space up to the ceiling, particularly when utilizing racking systems.

Moving Equipment

Moving equipment helps you transport goods around your warehouse. Here are some key types:

- Forklifts: These powerful machines can lift and move heavy pallets. They come in different sizes for various jobs.

- Pallet Jacks: These are simpler than forklifts. Workers use them to move pallets short distances.

- Conveyor Belts: These move items along a set path. They’re great for moving lots of goods quickly.

- Order Pickers: These machines help workers reach items stored high up. They make picking orders faster and safer.

Packaging Equipment

Packaging equipment helps you get goods ready for shipping. Some examples are:

- Stretch Wrap Machines: These wrap plastic around pallets to keep items secure.

- Box Makers: These machines create custom-sized boxes for your products.

- Label Printers: These print labels with important info about each package.

Safety Equipment

Safety equipment protects your workers and your goods. It includes various items such as ergonomic tools and efficient racking systems.

- Personal Protective Equipment (PPE) includes hard hats, safety shoes, and gloves.

- Safety Signs: These warn workers about dangers and show safe walking paths.

- Fire Safety Tools include fire extinguishers, alarms, and sprinkler systems.

How to Choose the Right Warehouse Equipment

Picking the proper selection of warehouse supplies is critical to running a good operation. Here’s how to implement effective material handling solutions:

Know Your Needs

Consider your warehouse needs, such as what kinds of goods you handle and how many. Are you dealing with pallet racking systems, mezzanine areas, or used warehouse equipment? Do you need warehouse supplies like hand trucks or industrial carts?

You must determine if you need to move heavy items using forklifts or handle small parts efficiently with totes or carton storage. Consider your material handling products, modular offices, pallet racking, and tools and equipment.

Whether you need dock equipment or a selection of warehouse supplies, optimizing your space utilization and warehouse racking should align with your specific storage requirements.

Check Your Space

Look at your warehouse layout, including available warehouse space, workspace, and existing warehouse infrastructure. How much floor space do you have? How can you utilize material handling solutions to optimize warehouse storage?

Consider space utilization when selecting management equipment, like pallet racking systems or modular shelving units. Ensure you have adequate warehouse storage solutions, such as racks and shelves, to maximize space vertically and horizontally.

Loading dock capabilities and inventory management are essential for streamlining your workflow and loading and unloading processes. Modular components like guardrails, mezzanines, or platforms can further improve efficiency and maximize the functionality of your warehouse space.

Also Read FN Logistics: Shipping Solutions, Delivered Differently with advanced warehouse management systems.

Think About the Future

Choose warehouse equipment that can grow with your business, whether adding racking systems, in-plant spaces, or increasing inventory management needs.

A wide selection of material handling products, like stackers, forklifts, industrial shelving, automated guided vehicles (AGVs), or platform trucks, can meet growing demands.

Optimize space with productive work environments, including pallet racks, modular shelving, and hopper systems. Tools like AMRs (Autonomous Mobile Robots) or AGVs can help protect your employees while controlling labor costs.

Extensive selection tools and loading dock equipment make managing warehouse racking and storage systems safe and efficient for future expansion.

It’s always better to have equipment like forklifts and stackers that can handle more than you need now rather than needing to replace under-capacity items quickly. Request a quote today for used warehouse equipment or modular solutions to ensure your warehouse remains adaptable for future growth.

Focus on Safety

Always pick equipment with good safety features. This protects your workers and can save you Money on insurance, especially with ergonomic equipment.

Consider Your Budget

Good warehouse equipment can be expensive, whether you’re looking for new or used options. But think about how much time and Money it can save you in the long run. Sometimes, spending more upfront on warehouse supplies can lead to significant savings later.

Get Training

Make sure your workers know how to use the equipment properly. Good training can prevent accidents and help your material-handling equipment, such as forklifts and pallet jacks, last longer.

The Benefits of Good Warehouse Equipment

Using the right warehouse equipment, like conveyors and racks, can bring many benefits to your operations:

Faster Work

Good warehouse products, like ergonomic pallet jacks, help your workers do their jobs faster. This will enable you to select equipment that is appropriately fitting.

Fewer Mistakes

Many types of warehouse equipment, including conveyors and pallet jacks, can help reduce errors. Barcode scanners, for example, can ensure the correct items go to the right places, optimizing your warehouse solutions.

Safer Workplace

Well-designed equipment can make your warehouse safer by incorporating modular guardrail systems. This means fewer accidents and happier workers.

Better Use of Space

Proper storage solutions let you use all your warehouse space well. This can save you money on rent or allow you to store more goods in your facility’s warehouse storage, especially if you add a mezzanine.

Happier Customers

When your warehouse runs smoothly, you can get orders out faster and more accurately. This leads to happier customers who will likely buy from you again, especially when your productivity is high.

Keeping Your Warehouse Equipment in Good Shape

Once you have your warehouse equipment, taking care of it is essential for efficient inventory management. Here are some tips:

Regular Checks

Look over your equipment often to catch any problems early, particularly with your forklifts and conveyors. This can prevent breakdowns and keep your workers safe.

Clean and Maintain

Keep your equipment clean and follow the manufacturer’s maintenance instructions. This modification will extend its lifespan and enhance performance, mainly if you utilize ergonomic designs.

Train Workers Well

Ensure all your workers know how to use the equipment properly, particularly the forklifts and pallet jacks. This prevents accidents and helps the equipment last longer.

Update When Needed

Your equipment requirements may evolve as your business expands, necessitating the addition of more racks or conveyors. Feel free to upgrade your material handling equipment, such as forklifts and conveyors, when needed.

Closing Thoughts

Good warehouse equipment is a big part of running a successful operation. It helps you work faster, safer, and smarter with the proper storage solutions, including racks and shelving.

Choosing the right tools and caring for them can make your warehouse more efficient and your business more profitable.

Remember, the best warehouse management equipment for you depends on your specific needs. Consider what you need now and what you might need in the future, such as additional shelving or a mezzanine.

With the right used warehouse equipment, including forklifts and pallet jacks, your warehouse can become a well-oiled machine that helps your business.

FAQs:

What is the most critical warehouse equipment?

Forklifts are often considered the most important. They help move heavy loads quickly and safely, making them essential for most warehouses, especially when considering warehouse safety.

How often should I replace warehouse equipment?

It depends on use and maintenance. Generally, we replace forklifts every 10,000-12,000 hours, pallet jacks every 3-5 years, and conveyor belts every 5-10 years.

Can small businesses afford good warehouse equipment?

Yes. Many options exist for small businesses, including renting or leasing dock equipment. Start with essential items and add more as your business grows.

What safety equipment is a must-have in warehouses?

Essential safety equipment includes hard hats, safety shoes, high-visibility vests, fire extinguishers, first aid kits, and proper lighting for effective warehouse management systems.