Table of Contents

Today’s global logistics environment demands actionable, visible supply chain-t1 strategies that drive resilience and efficiency across the first tier of suppliers. Visible supply chain-t1 refers to real-time tracking, transparency, and systematic oversight of Tier-1 supplier data, activities, and performance. Tier-1 suppliers are your direct vendors who provide finished components, raw materials, or services essential to production and delivery.

Without visibility at this level, disruptions escalate into costly delays, inventory mismatches, and weakened demand forecasting. In 2025, 43% of companies still lack basic visibility into these critical partners. This gap erodes competitiveness and limits response agility when market conditions shift suddenly. Achieving strong visibility at Tier-1 unlocks operational benefits, enhances supplier relationships, and strengthens your supply chain’s risk posture.

Later sections break down optimization techniques, performance indicators, implementation barriers, technology roles, and best practices that equip logistics leaders with measurable outcomes. Data shows companies with strong supply chain visibility enjoy lower costs, faster disruption responses, and improved fulfillment reliability.

This article guides you through building and optimizing a visible supply chain-t1 framework supported by context, metrics, and operational insights.

Why Visible Supply Chain-T1 Matters in 2025

Visible supply chain-t1 means you can see orders, inventory, movements, and supplier risks at the first tier before issues escalate.

In 2025, supply chain disruption risks remain material. For example, 82% of global supply chain leaders report tariffs affecting flows and causing supplier costs to rise by 39%. These macro pressures make Tier-1 visibility essential for pivoting quickly from threat to action.

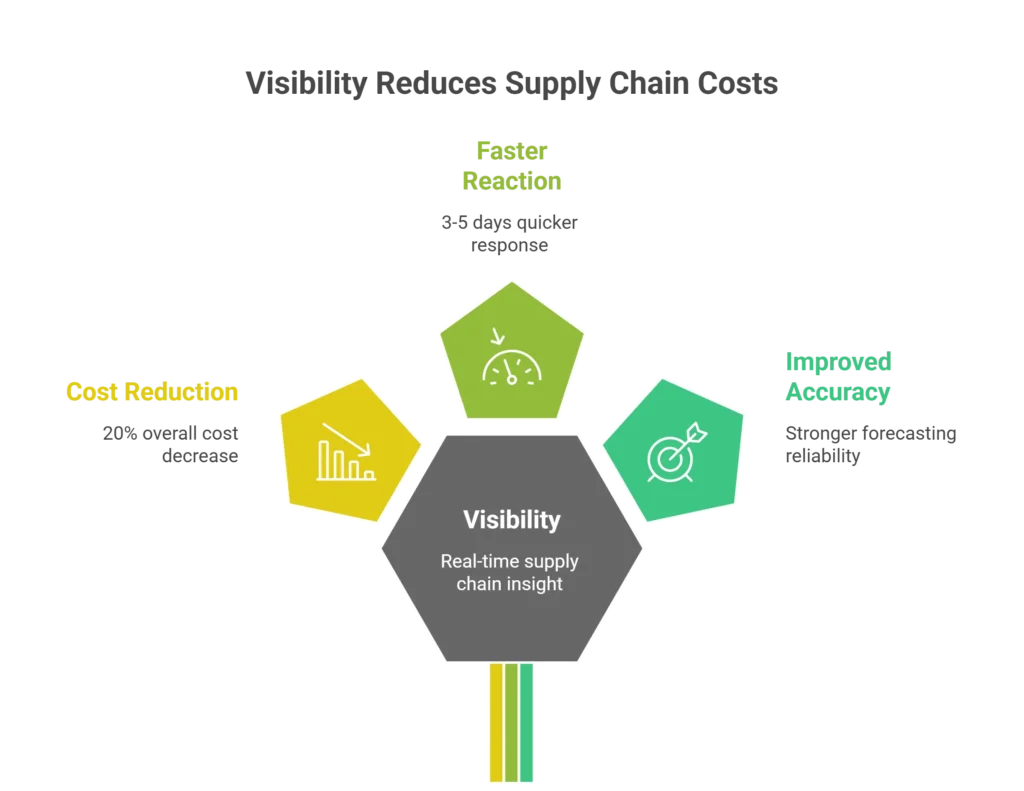

Visibility allows logistic teams to monitor supplier delivery reliability, lead-time variability, and quality metrics with precision. Data from industry reports shows real-time insight correlates with a 20% reduction in overall supply chain costs and faster reaction to disruption by 3–5 days compared to less visible competitors. Without this transparency, delays stack and forecasting accuracy weakens, undermining service commitments to customers.

In fact, 59% of brands cite limited visibility as a core weakness in their disruption response strategies. Thus, investing in visible supply chain-t1 is not optional for logistics teams; it’s an operational imperative that drives predictability and performance in uncertain markets.

What Happens When Tier-1 Visibility Is Poor

When you cannot track performance at Tier-1 suppliers, the consequences ripple throughout your network:

- Order delays cascade into customer dissatisfaction.

- Unplanned inventory stockouts raise fulfillment costs.

- Inaccurate forecasting triggers waste or missed sales opportunities.

- Risk mitigation becomes reactive instead of proactive.

These results stem directly from gaps in real-time data, shared processes, and integrated systems across supplier relationships.

Core Components of Visible Supply Chain-T1

For visible supply chain-t1, you need four foundational components. These work together and create measurable outcomes:

1. Real-Time Data Integration

Connecting ERP, SCM, and supplier systems ensures that procurement, logistics, and planning teams operate from unified information. Real-time integration reduces blind spots and supports decision speed. ~20% cost savings are typical when visibility tools replace manual tracking.

2. Supplier Performance Metrics

Track these essential Tier-1 indicators:

- On-Time Delivery Rate (% of orders delivered on schedule).

- Lead Time Variability (days standard deviation).

- Quality Rejection Rate (% of defects).

- Fulfillment Accuracy (% of orders correctly processed on first pass).

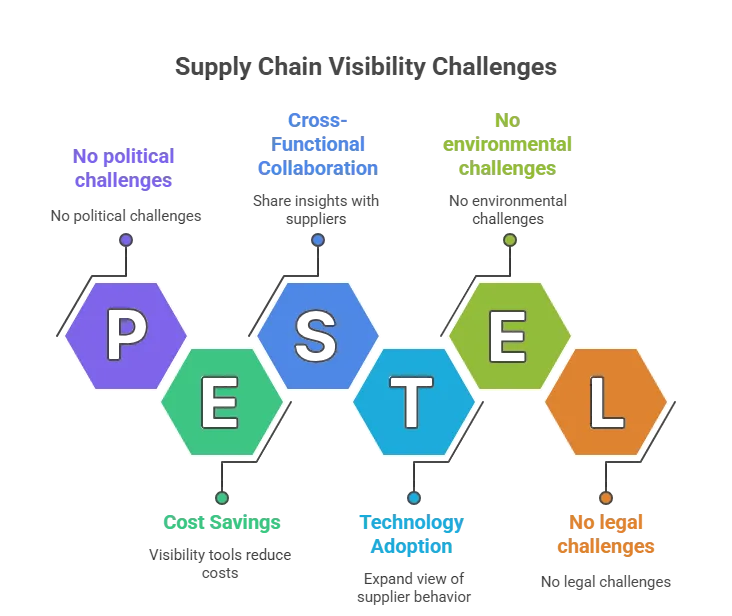

3. Technology Adoption

Visibility platforms (e.g., real-time trackers, AI analytics) expand your view of supplier behavior and anomalies. Leading solutions use IoT sensors, cloud analytics, and AI forecasting to detect delays before they impact operations.

4. Cross-Functional Collaboration

Operations, procurement, and IT must share insights continuously with suppliers. Standardized scorecards and quarterly performance reviews keep all parties aligned on expectations.

Table: Tier-1 Visibility Components and Benefits

| Component | Primary Benefit | Key Metric |

|---|---|---|

| Real-Time Data Integration | Faster decisions | Data latency (min) |

| Supplier Performance Metrics | Predictable outputs | On-Time Delivery (%) |

| Technology Adoption | Proactive alerts | Exception frequency (events) |

| Collaboration Practices | Shared accountability | Supplier Scorecard Index |

Implementing a Visible Supply Chain-T1 Strategy

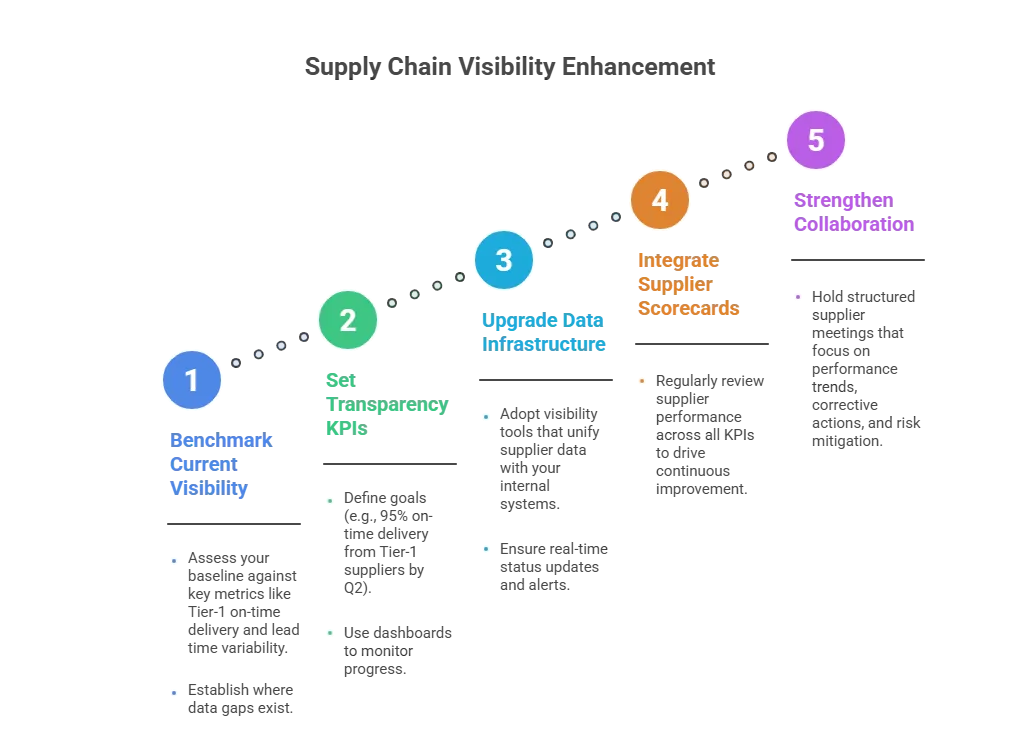

Start with a clear roadmap and measurable milestones to make visible supply chain-t1 workable in your logistics operations.

Step 1: Benchmark Current Visibility

Assess your baseline against key metrics like Tier-1 on-time delivery and lead time variability. Establish where data gaps exist.

Step 2: Set Transparency KPIs

Define goals (e.g., 95% on-time delivery from Tier-1 suppliers by Q2). Use dashboards to monitor progress.

Step 3: Upgrade Data Infrastructure

Adopt visibility tools that unify supplier data with your internal systems. Ensure real-time status updates and alerts.

Step 4: Integrate Supplier Scorecards

Regularly review supplier performance across all KPIs to drive continuous improvement.

Step 5: Strengthen Collaboration

Hold structured supplier meetings that focus on performance trends, corrective actions, and risk mitigation.

Visible supply chain-t1 is not a one-time project. It’s a continuous improvement cycle that evolves with market conditions and internal capabilities.

Key Technologies Enabling Visibility

Leveraging modern tech makes visible supply chain-t1 more precise and scalable.

Cloud Platforms: Centralize data streams from suppliers and logistics partners.

IoT and Sensors: Provide real-time movement and condition tracking for goods.

AI Analytics: Predict supply risks based on trends and external events.

Blockchain: Ensures data integrity and tamper-proof records across partners.

For example, advanced visibility platforms reduce manual errors and free planner hours for strategic work. These tools also improve coordination with suppliers by automating alerts when thresholds are breached.

Overcoming Visibility Barriers

Despite clear benefits, companies struggle with Tier-1 visibility due to:

- Data silos across systems.

- Resistance from suppliers to share sensitive data.

- Technology integration challenges.

Overcome these by prioritizing standardized data formats, clear security agreements with partners, and phased technology rollouts.

Business Impact and ROI

Investing in a visible supply chain-t1 delivers measurable value. Firms with advanced visibility often experience:

- Lower fulfillment costs: ~20% reduction versus peers with limited visibility.

- Faster disruption response: 3–5 days quicker mitigation.

- Stronger supplier performance: Higher delivery accuracy and reliability.

These outcomes enhance customer satisfaction and competitive positioning. Leaders who invest in visibility also report improved demand forecasting and fewer last-mile surprises.

Bottom Line

Making your visible supply chain-t1 strategy operational is essential for modern logistics excellence. It strengthens supplier relationships, reduces costs, improves delivery reliability, and accelerates decision-making. To succeed, start with strong data integration, clear KPIs, and collaborative processes across functions and suppliers. Align technology investments with measurable business outcomes. With visible supply chain-t1 as a foundation, your logistics operations will be more resilient, agile, and predictable in 2026 and beyond.

Disclaimer:

This article provides general informational content about visible supply chain-t1 management and optimization. It is not intended as professional, legal, or financial advice.