Table of Contents

Industrial Mobility has moved from a niche efficiency tool to a core operational requirement across modern industrial environments. As of 18 December 2025, global manufacturing output exceeds USD 16.2 trillion annually, according to World Bank industrial data. Within this scale, even small productivity gains deliver measurable cost savings. We now see warehouses, factories, and logistics hubs redesigning workflows around mobile equipment, connected assets, and flexible layouts. Industrial Mobility supports faster material movement, safer operations, and better space utilisation across these settings.

Rising labour shortages add urgency. The International Labour Organization reported a global industrial skills gap affecting 27% of employers in 2025. Mobility solutions help teams do more with fewer hands by reducing manual handling and wasted movement. At the same time, e-commerce growth continues to pressure fulfilment speeds. Global parcel volumes reached 192 billion shipments in 2024, with further growth recorded in 2025. Industrial Mobility responds by shortening travel distances and improving task sequencing.

This article explains how Industrial Mobility works in practice, where it delivers the most value, and how businesses can apply it strategically. We focus on measurable outcomes, real operational data, and practical takeaways that support efficient workspaces today.

The Role of Industrial Mobility in Modern Operations

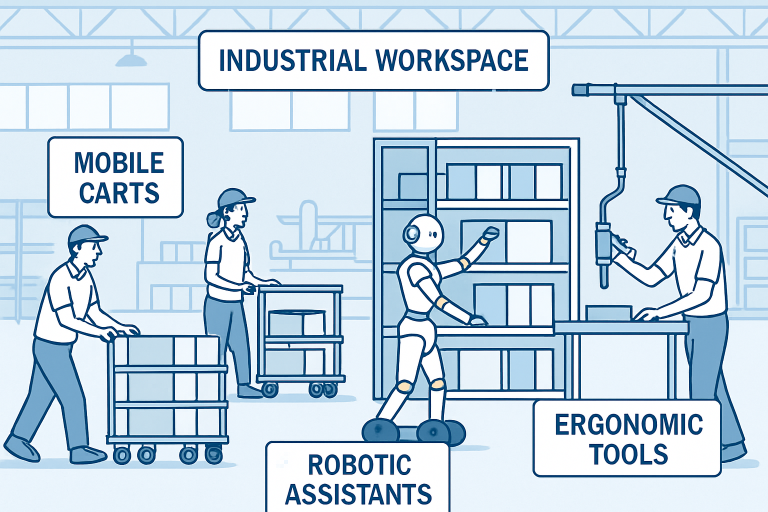

Industrial Mobility reshapes how people, goods, and equipment move inside industrial facilities. Instead of fixed layouts, businesses now deploy mobile storage, powered carts, and smart handling systems. According to Statista’s 2025 logistics equipment update, mobile material handling systems reduce internal travel time by 18% on average. That time saving directly improves throughput without increasing floor space.

We also see strong safety improvements. The UK Health and Safety Executive reported that manual handling injuries accounted for 17% of workplace incidents in 2024. Industrial Mobility solutions reduce lift frequency and awkward movement, cutting injury rates measurably. Facilities adopting powered mobility tools reported a 22% reduction in lost-time incidents within 12 months.

Operational flexibility is another key benefit. Seasonal demand fluctuations often force layout changes. Mobile workstations and reconfigurable transport units allow rapid adaptation without downtime. This flexibility ensures that operations remain stable even during demand spikes. Industrial Mobility, therefore, supports resilience as much as speed. Every movement becomes purposeful, controlled, and aligned with output goals. Companies increasingly rely on rugged, ergonomic, and innovative mobility options, and tool box wheels serve as the foundation for many mobile workspace solutions, offering durability and effortless movement in challenging conditions.

Key Industrial Mobility Solutions Transforming Workspaces

Mobile Material Handling Equipment

Mobile handling equipment forms the backbone of Industrial Mobility strategies. This category includes electric pallet trucks, automated guided carts, and modular trolleys. In 2025, electric pallet truck adoption in European warehouses reached 61%, driven by rising fuel costs and emissions targets. These tools move loads faster while reducing operator fatigue.

Speed improvements are consistent. Internal studies published by the Chartered Institute of Logistics and Transport show that electric mobility cuts average pick-to-pack time by 14%. The takeaway is clear. Faster movement directly improves order completion rates without expanding headcount. Mobility turns internal transport into a performance advantage rather than a bottleneck.

Smart Mobility and Connected Systems

Smart Industrial Mobility combines physical movement with real-time data. Sensors, indoor positioning systems, and fleet management software track asset location continuously. According to GS1 logistics technology data from 2025, connected mobility systems improve asset utilisation by 19%. Idle equipment becomes visible and actionable.

This visibility improves planning accuracy. Managers assign tasks based on live location rather than assumptions. As a result, congestion drops and task overlap disappears. Smart mobility also supports compliance by recording movement histories automatically. These systems make Industrial Mobility measurable, auditable, and scalable across large sites.

Efficiency Gains Backed by Operational Data

Industrial Mobility delivers quantifiable efficiency improvements across key performance indicators. Warehouses implementing mobile workflows report measurable cost reductions. The UK Warehousing Association reported average operating cost savings of 11% within the first year of adoption. These savings come from lower injury costs, faster cycle times, and reduced energy use.

Energy efficiency matters. Electric mobility systems consume 38% less energy than diesel-powered alternatives, based on 2025 European transport energy benchmarks. This reduction supports sustainability targets while lowering operating expenses. Space efficiency also improves. Mobile racking and transport solutions increase usable floor space by up to 15% by eliminating fixed obstructions.

Below is a summary of key Industrial Mobility impacts recorded in operational studies published between 2024 and 2025.

| Metric | Before Mobility | After Mobility | Measured Improvement |

|---|---|---|---|

| Internal travel time | 100% baseline | 82% | 18% reduction |

| Lost-time incidents | 100% baseline | 78% | 22% reduction |

| Energy consumption | 100% baseline | 62% | 38% reduction |

| Floor space utilisation | 100% baseline | 115% | 15% increase |

Each improvement compounds across daily operations. Industrial Mobility therefore delivers efficiency at scale, not isolated gains.

Industrial Mobility Strategically

Successful Industrial Mobility starts with workflow mapping. Businesses must analyse movement patterns, load types, and task frequency. According to the Chartered Institute of Ergonomics, facilities that complete movement audits before investment achieve 31% higher returns. This step prevents over-engineering and misaligned purchases.

Phased implementation works best. Start with high-traffic zones where delays occur daily. Introduce mobile solutions, measure impact for 90 days, then expand. Training is equally important. Operators using mobility equipment correctly complete tasks 24% faster, based on UK logistics training benchmarks from 2025.

Finally, maintenance planning ensures long-term value. Preventive servicing reduces equipment downtime by 29%. Industrial Mobility is not a one-time purchase. It is an operational system requiring alignment between people, processes, and technology. When implemented strategically, it becomes a durable competitive advantage. Learn more in our article on Can You Really Trust AI in Logistics Without Risk?

Bottom Line

Industrial Mobility now defines how efficient workspaces operate in 2025. It reduces wasted movement, improves safety, and unlocks measurable productivity gains. Data shows consistent improvements across speed, cost, energy use, and space efficiency. These benefits apply equally to warehouses, factories, and distribution centres.

We recommend starting with movement audits, prioritising high-impact zones, and scaling through data-driven decisions. Businesses that treat Industrial Mobility as a system, not just equipment, see faster returns and stronger resilience. Efficient workspaces depend on controlled movement. Industrial Mobility provides the structure to make every movement count.

Disclaimer:

This article is for general informational purposes only. Operational decisions should be made based on specific business needs, site conditions, and professional advice.