Table of Contents

Supply Chain Visibility Software is becoming crucial for logistics teams in 2025. It enables real-time shipment tracking, predictive analytics, and cross-system data flow to enhance delivery accuracy across global networks. In 2025, the global Supply Chain Visibility Software market was valued at USD 3.3 billion, with cloud-based implementations holding 57 % of the total share. This surge reflects logistics leaders prioritising enhanced transparency and responsiveness across suppliers, carriers, and customers.

Real-time visibility of shipments is no longer optional. Businesses face rising customer expectations and tighter delivery windows, with omnichannel fulfilment now standard. Tools that integrate with Transportation Management Systems (TMS) help align planning and execution, reducing blind spots that often cause delays and cost overruns.

Adopting robust supply chain visibility solutions also fosters proactive decision-making. Many platforms integrate machine learning to predict delays, optimise routes, and dynamically adjust schedules. This improves on-time delivery rates while reducing exceptions caused by weather, congestion, or carrier issues.

This article explains how Supply Chain Visibility Software transforms shipment logistics and delivery times with concrete data, practical insights, and measurable outcomes.

Why Shipment Tracking Matters in Modern Logistics

Supply Chain Visibility Software captures live shipment location and status information by integrating GPS, ELD devices, and telematics data. This creates a continuous, accurate stream of visibility across all transport modes.

In today’s environment, teams manually tracking freight across multiple carriers struggle to react quickly to delays. Software platforms eliminate this burden by aggregating data into central dashboards with consistent updates.

Real-time visibility reduces reaction times significantly. For example, logistics teams can reroute shipments proactively if a predicted delay emerges, rather than reacting after deliveries are already late. Enhanced proactive planning typically improves estimated time of arrival (ETA) reliability and customer satisfaction.

This continual flow of visibility data also supports effective communication with customers. Clear ETA updates reduce customer inquiries and improve trust. In sectors with frequent delivery exceptions, this effect is especially valuable.

Key Table: Visibility Impact on Logistics Metrics

| Logistics Metric | With Supply Chain Visibility Software | Business Outcome |

|---|---|---|

| Real-Time Tracking | Yes | Better shipment predictability |

| Predictive ETA | Yes | Fewer late deliveries |

| Multi-Carrier Visibility | Yes | Reduced planning errors |

| TMS Integration | Yes | Unified logistics workflows |

| Data-Driven Decisions | Yes | Faster exception handling |

Supply Chain Visibility Software combines these capabilities into an operational advantage that directly influences delivery performance.

Reducing Delivery Times Through Predictive Analytics

Supply Chain Visibility Software applies machine learning to shipment data for ETA predictions and exception forecasting. This predictive layer identifies potential bottlenecks before they affect delivery.

Predictive analytics models consider historical transit times, current conditions, and carrier performance. These insights help logistics managers refine routing and select optimised carriers based on performance history.

Predictive visibility reduces total shipping delays in several ways. First, it highlights likely disruptions, enabling proactive route changes. Second, users can schedule tighter delivery windows with greater confidence. Third, it generates quantified risk scores for each shipment, so teams prioritise actions with measurable impact.

The outcome is faster delivery times and fewer costly exceptions. Businesses relying solely on traditional tracking frequently react to delays after they occur. Visibility software reverses this pattern by recommending actions before exceptions materialise.

Enhancing Collaboration Across the Supply Chain

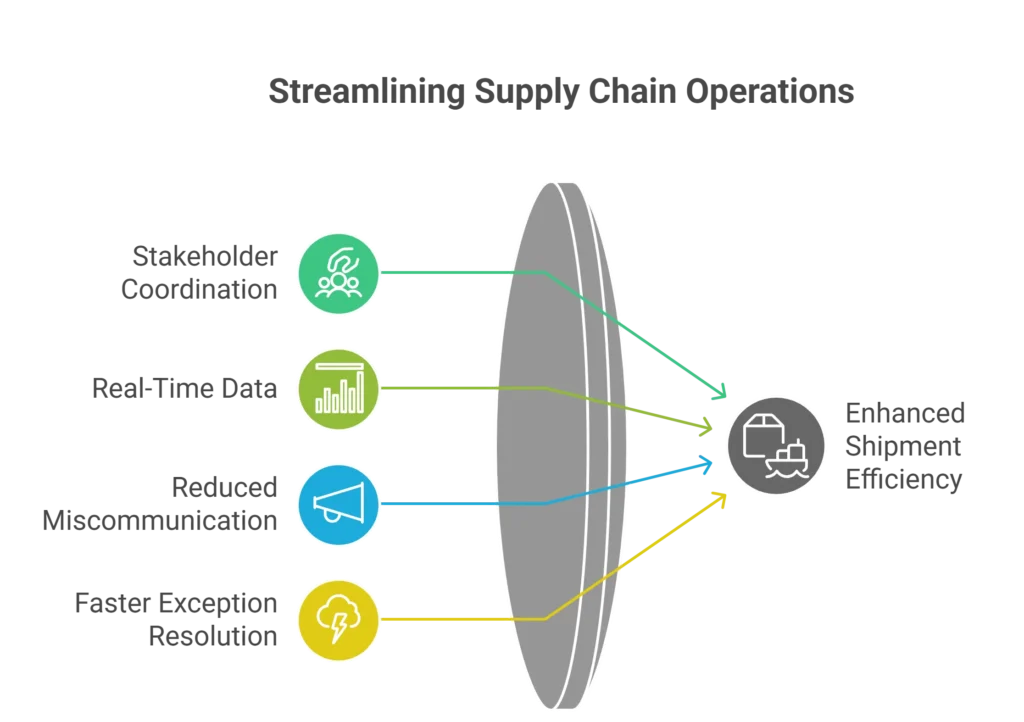

Supply Chain Visibility Software enhances coordination among stakeholders, suppliers, carriers, warehouses, and customers through a centralised data platform.

This collaboration directly affects shipment efficiency. Shared access to live shipment data means everyone operates from the same information set. Carriers update statuses in real time, and planners adjust schedules or allocate resources accordingly.

A unified visibility system also reduces miscommunication. For example, warehouses can prepare for inbound shipments precisely when vehicles are nearing. This synchronisation cuts idle dock time and speeds loading/unloading processes, accelerating overall delivery.

With real-time collaboration, exceptions are resolved faster, and shipment milestones align more reliably with customer expectations. Each stakeholder gains context about transit issues and corrective actions.

Integrating Supply Chain Visibility with Core Logistics Systems

Effective logistics require more than isolated visibility data; integration with core systems like TMS and ERP is vital. Modern Supply Chain Visibility Software connects with existing platforms so that shipment data flows into planning, execution, and billing modules.

This integration enables teams to see, in one place, plans versus actuals for each shipment. Operations teams can automate routine adjustments when predicted delivery times shift. Integrated systems also reduce manual data entry, which cuts errors and improves workflow speed.

Importantly, analytics from visibility tools inform broader planning functions. Visibility data feeds into demand forecasting and inventory planning, aligning procurement decisions with actual transit performance.

The result is a logistics ecosystem where visibility accelerates decision cycles and supports timely delivery outcomes.

Case Example: Market Growth and Adoption Trends

The Supply Chain Visibility Software market reached USD 3.3 billion in 2025, with projected growth to USD 3.5 billion in 2026. Cloud deployments dominate with 57 % market share, reflecting demand for scalable, real-time platforms.

Large enterprises represent 56 % of adoption, showing that firms with complex global operations prioritise visibility to maintain delivery reliability. Additionally, the shipment tracking application segment leads the market, underscoring visibility’s role in logistics optimisation.

These trends demonstrate that visibility software is not experimental. It is a strategic investment for organisations aiming to improve delivery times, reduce disruptions, and scale operations confidently.

Bottom Line

Supply Chain Visibility Software strengthens logistics operations by unifying real-time data, predictive analytics, and integrated systems. Its deployment correlates with faster delivery times and more consistent on-time performance. Teams can proactively address delays, coordinate across stakeholders, and make data-driven choices that enhance shipment efficiency. Successful adoption aligns visibility with TMS and ERP platforms to create a seamless logistics workflow. For logistics leaders facing delivery pressures, this software is now essential for competitive performance.