Table of Contents

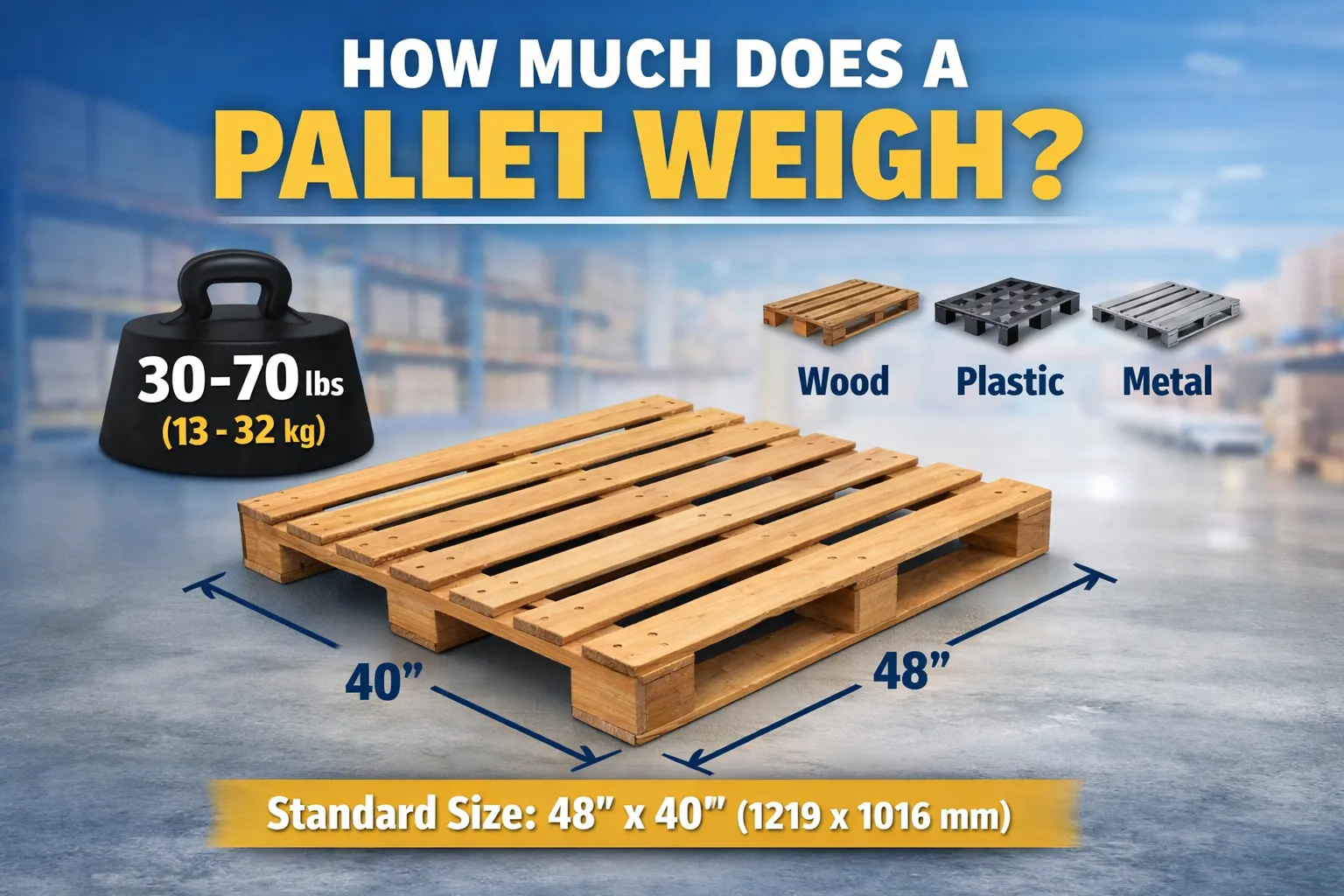

In logistics, we must know How Much Does a Pallet Weight to plan shipping, storage costs, and safety. A standard pallet is the base platform used to move and store goods in warehouses and on transport vehicles. In North America, a 48″ x 40″ pallet is most common, and its empty weight usually falls between 30 and 48 pounds (14 to 22 kg). Wooden pallets make up the majority of the market because they balance strength and cost for general freight needs.

The weight of an empty pallet affects freight charges since carriers often charge by total shipment weight. Lighter pallets reduce fuel use, lower handling strain, and cut overall transport costs. Plastic and metal pallets weigh differently, with plastic options often under 30 pounds and metal platforms reaching 80 to 120+ pounds. Material choice changes how much a pallet weight adds to your shipment.

Knowing exact pallet weights also improves storage planning. Warehouse racks and stacking limits depend on knowing both pallet tare weight and load weight. This article breaks down standard pallet weights by type, material, and use case. It finishes with clear takeaways for logistics planning and cost control.

Standard Pallet Basics and Typical Weights

We start with the most common question: How Much Does a Pallet Weight for general logistics? The North American standard pallet size is 48×40 inches. An empty wooden pallet of that size usually weighs 35 to 40 pounds (16 to 18 kg).

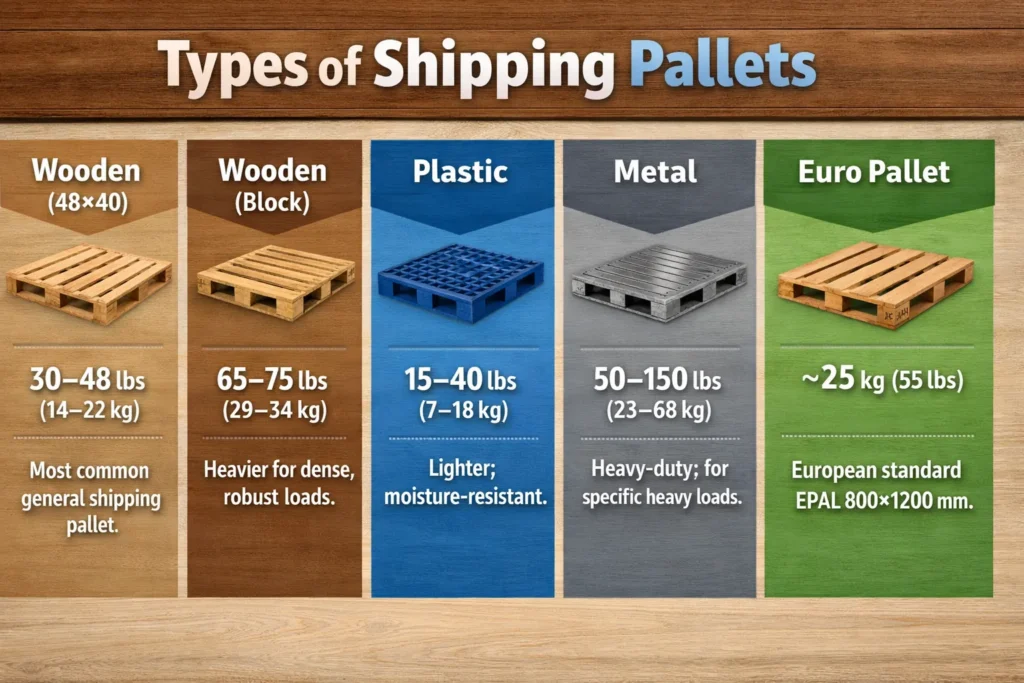

This standard pallet weight serves as a baseline for planning. Table 1 shows typical empty pallet weights by material and type. Logistics teams should reference this when calculating total shipment mass.

Typical Empty Pallet Weights (2025 Data)

| Material | Weight Range | Notes on Use |

|---|---|---|

| Wooden (48×40) | 30–48 lbs (14–22 kg) | Most common general shipping pallet. |

| Wooden (block) | 65–75 lbs (29–34 kg) | Heavier for dense, robust loads. |

| Plastic | 15–40 lbs (7–18 kg) | Lighter; moisture-resistant. |

| Metal | 50–150 lbs (23–68 kg) | Heavy-duty; for specific heavy loads. |

| Euro Pallet | ~25 kg (55 lbs) | European standard EPAL 800×1200 mm. |

Knowing material differences helps logistics managers allocate pallet weight into freight totals. Pallet tare weight is always added to net load weight to produce the gross shipment weight that carriers bill against.

Material also affects durability. Plastic pallets resist moisture and pests, so they weigh less. Metal pallets serve heavy industrial use but add significant tare weight, raising transport costs.

Wooden Pallets: The Most Common Standard

Wood pallets still dominate global freight because they balance cost and strength. When we ask How Much Does a Pallet Weight for wood, the answer depends on the wood type and the moisture content. Most standard wooden pallets range from 30 to 70 pounds (14 to 32 kg).

Why Wood Pallet Weight Varies

Wood type is a key factor. Softwoods like pine or spruce are lighter and typically fall on the lower end of the weight range. Hardwoods such as oak or maple weigh more due to higher density. Moisture content also changes the weight; wet wood can weigh up to 20 pounds more than dry pallets

Design and construction matter too. Block pallets use wooden blocks instead of stringers for support. This strengthens the pallet but also adds weight. A standard stringer pallet will often weigh less than a block pallet of the same footprint.

When planning freight, check the specific pallet weight from your supplier rather than assuming an average. Even within the 48×40 format, actual weights differ based on species, moisture, and build style.

Pallet Material Comparison and Logistics Impact

Different materials change how much every pallet weighs and how it influences logistics costs.

Plastic vs Wooden vs Metal

Plastic pallets typically weigh 15 to 40 pounds (7 to 18 kg). They save weight on shipments and resist environmental factors, so they are ideal for export and food-chain logistics.

Metal pallets are stronger but heavier, often between 50 and 150 pounds (23 to 68 kg). These are used in heavy manufacturing or when pallets are reused thousands of times. The extra weight increases fuel use and handling strain.

Wood pallets remain the logistics standard because they provide a compromise between weight, strength, and cost. Most standard 48×40 wooden pallets weigh 30–48 pounds. Learn more in our article on Warehousing and Logistics: Key Differences Explained.

Choosing the Best Option

Choose plastic when you need a lighter shipment weight or consistent hygiene. Choose wood when cost and general strength matter. Choose metal only for heavy industrial loads or reuse requirements. Each material choice must weigh tare weight against durability and total freight cost.

How Pallet Weight Affects Shipping Costs

We must understand that carriers calculate shipping costs using total weight. That total includes pallet tare weight plus cargo weight.

For a shipment using standard wooden pallets weighing 40 pounds each, eight pallets add 320 pounds before cargo is loaded. If cargo weighs 4,600 pounds, the gross shipping weight becomes 4,920 pounds. Carriers like UPS or freight brokers price per total weight. Heavier pallets increase linehaul and fuel charges. It’s a direct cost variable.

Knowing pallet weights can also impact container utilization. Lighter pallets allow more cargo per container without exceeding weight limits. In air freight, where weight limits are strict, every pound counts.

Bottom Line

Understanding How Much Does a Pallet Weight is essential in logistics planning. Standard pallets like the 48×40 wooden type usually weigh between 30 and 48 pounds. Other materials like plastic and metal vary widely. Exact pallet weight affects freight cost, handling, and storage planning. Always integrate specific pallet weights into your shipment calculations to control costs and meet carrier requirements. Accurate weight data helps optimize logistics decisions.

Disclaimer:

The information in this article is provided for general educational purposes only.