Table of Contents

Separating solids from liquids is a vital process in many industrial applications. While traditional clarifiers and settling tanks separate particles, sediment, and solids using gravity, decanter centrifuges use continuous rotation to induce centrifugal forces up to 4000 times stronger than gravitational force.

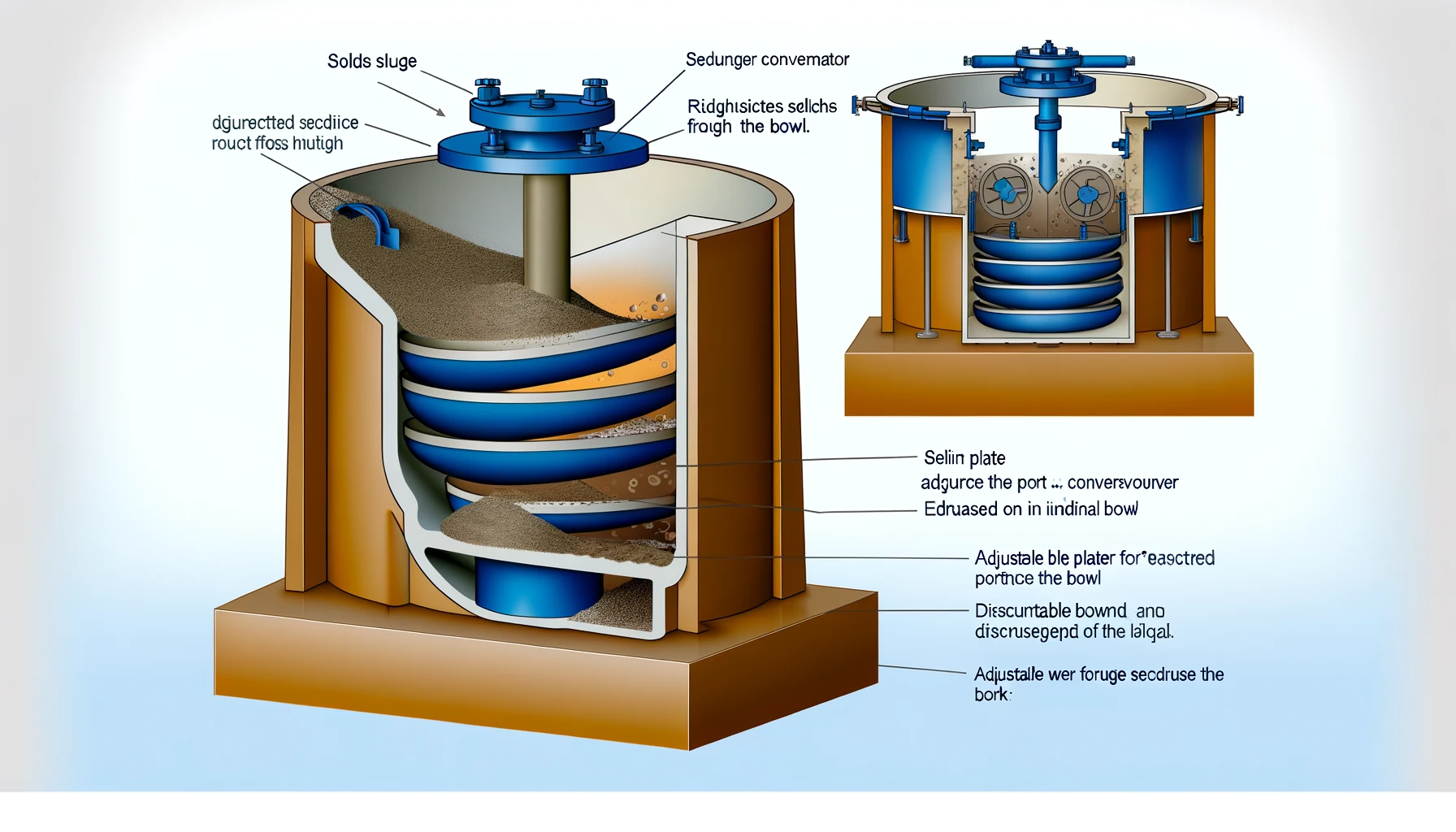

The rotation carries the slurry to the end of the bowl and onto a conveyor, which then scrolls the solid material to the solid discharge ports. It eliminates the need to elevate the decanter for sludge collection.

Reduced Environmental Impact

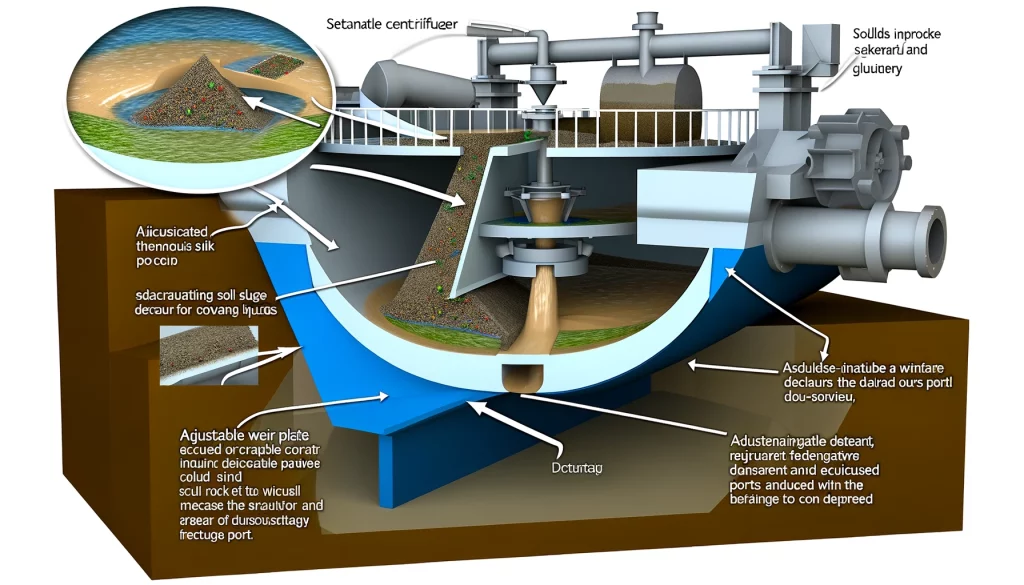

Decanter centrifuges separate solid materials from liquids continuously. They can help settle pond elimination, recover water, and meet environmental regulations.

In a decanter centrifuge, sludge enters through an internal conveyor inside the rotating bowl tube for separation based on gravitational forces. The solids settle against the wall of the container while the liquid moves freely through ports at the top of the bowl.

To avoid excessive wear on the sludge conveyor and sludge discharge ports, some designs include an adjustable weir plate to adjust the diameter of the port openings. These adjustments reduce the discharged sludge and allow more solids to be transported through the beach area.

Reduced Energy Consumption

A decanter centrifuge requires a lot of energy to accelerate the separation medium up to operating speed. However, the separated solids are ejected intermittently and thus generate energy losses. It can result in a surge in drive motor current or even power loss.

It can be overcome with the help of a decanter centrifuge design that uses Power Plates to recover rotational energy for energy regeneration and cost savings.

Another way to reduce energy consumption is through careful sizing of the machine. For example, the differential speed must be appropriately set to optimize the cake’s dryness. A lower differential speed means more time in the centrifuge and a dryer cake, while a higher differential speed leads to less centrifugation and a wetter cake. Both these factors must be balanced to achieve optimal performance and maximum efficiency.

Increased Product Quality

The decanter centrifuge operates on accelerated sedimentation using high-speed rotation to increase the force of gravity, creating a physical separation. The denser solid particles move towards the bowl wall and push the liquid outward, leaving a concentric inner layer – or pond – inside the machine.

Dampers are used to vary the depth of the pond as required. A screw conveyor (also called a drill or a screw/spiral) rotates at a speed different from the bowl. It enables the drill to scrape or push the solids collected along the tapered section of the bowl – or beach – toward the decanter centrifuge’s solids discharge ports.

Decanter centrifuges can handle varying concentrations of solids depending on the type and frequency of the sludge ejection system used in the process. To maximize decanter centrifuge performance, the differential speed should be appropriately set to ensure the best possible quality of the cake solids. This is vital in maintaining a high-quality dewatered product, particularly for landfill or liquid land application uses.

Increased Product Profits

Decanter centrifuges are used in many different industries to separate solids and liquids. They are needed for waste management, oil and gas drilling, manufacturing, food processing, hemp, and more.

When separating barite from drilling fluid, the goal is to lower the drilling mud’s plastic viscosity so that penetration rates increase and the wear on drill bits and mud pumps is reduced. Decanter centrifuges help achieve this by reducing the quantity of mud makeup required.

Decanters process the froth flotation sludge from exhaust gas cleaning directly on-board, significantly reducing its volume and saving significant costs. It makes a big difference in preventing sludge from becoming toxic and threatening marine life.

The result is less maintenance time, shorter downtimes, and increased product profits. Moreover, the self-cleaning machine with a 316L duplex stainless steel bowl, spray-coated with tungsten carbide hard-surfacing and satellite erosion-resistant inserts, reduces the chemicals and solvents needed for cleaning.