Table of Contents

The Rising Importance of Reliable Marine Electrical Systems

The electrical infrastructure of a vessel is primarily composed of marine-grade components and meticulous system design, supporting various systems like digital radars and waste management. However, at-sea electrical incidents often result from improper installations or poor maintenance. Marine environments, including saltwater corrosion, high humidity, and vibration, demand higher performance and durability standards for electrical parts.

As marine operations become more automated, reliable electrical systems are crucial. Every vessel relies on safe and consistent electrical power for navigation, communication, propulsion, and basic amenities. Unplanned failures can lead to hazardous situations, loss of maneuverability, or complete power loss at sea, sometimes cascading into life-threatening emergencies. By focusing on proven system architecture and using robust marine engine room parts, vessel owners and operators can significantly improve reliability and safety on the water. Proper cable management, corrosion-resistant components, and regular maintenance routines are essential to maintaining system integrity over time. Investing in quality parts and thoughtful design today helps prevent costly failures and downtime tomorrow.

Key Components Found in Modern Marine Electrical Installations

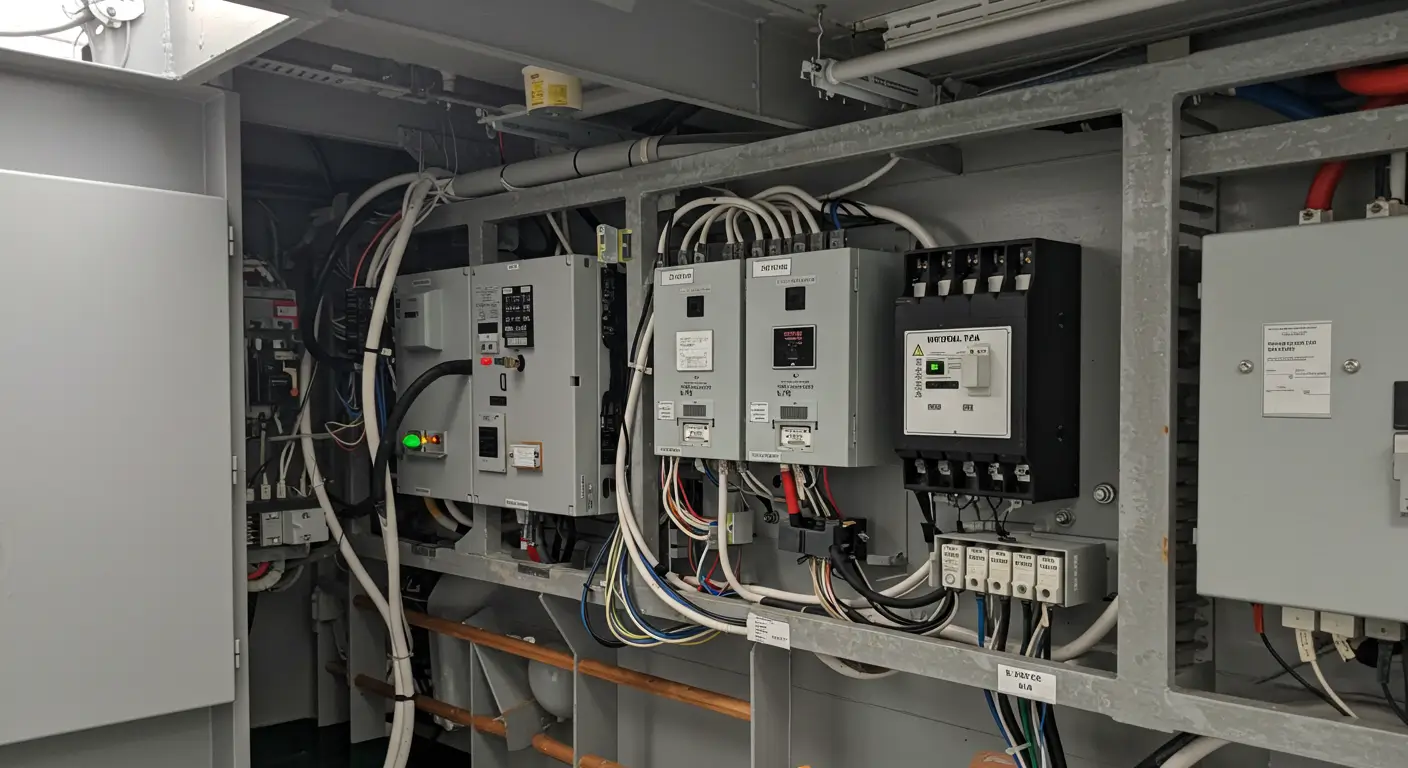

A modern marine electrical installation includes circuit breakers, fuse blocks, bus bars, terminal blocks, and marine connectors. Circuit breakers and fuse blocks protect electronics from damage, while switch panels provide centralized control over vital systems. Bus bars distribute electrical current smoothly, reducing voltage drop and organizing wiring. Marina batteries are engineered for deep-cycle requirements, supporting main engine starts and uninterrupted auxiliary power. Isolation switches allow complete separation of critical power sources in emergencies. Marine-grade hardware is essential for seafaring applications, as it can handle salt spray, constant jostling, and extreme temperature shifts. Only certified marine-grade supplies are necessary for every seafaring application.

Top Safety Features in Today’s Marine Electrical Design

Safety is a crucial aspect of maritime electrical work, requiring features like weather-sealed wiring, double insulation, and robust protective housings. GFCIs, particularly in wet or food-preparation areas, guard against electric shocks. Clearly labeled circuit panels and disconnect switches facilitate quick shutdowns. Vibration-proof fastenings for sensitive electronics increase component longevity and reduce accidental disconnections. Marine-grade insulation, rugged enclosures, color-coded wiring, and securely locked connectors are also essential.

How Smart Technology Is Shaping Marine Electrical Components

Digitalization is revolutionizing vessel monitoring and management. Modern boats use smart panels and networked monitoring systems to collect and analyze data on battery voltages, onboard loads, and environmental conditions. This information is relayed through touch-screen displays or mobile apps, enabling operators to make quick decisions remotely. Predictive alerts allow engineering teams to intervene before minor issues become major malfunctions. Advanced vessels now feature automated load shedding, generator start/stop logic, and digital control of lighting or HVAC, improving efficiency and enhancing safety.

Also Read: Common Electrical Issues in Homes and Practical Solutions

Energy Efficiency on the Water: Why It Matters

Marine operators are increasingly adopting energy-efficient electrical components, such as LED lighting, smart inverters, and solar panels, to control costs and minimize environmental impacts. These systems use less power, reducing reliance on fuel-driven generators, reducing emissions, and extending the life of engine-based components. Efficient systems promote quieter operation, a crucial quality-of-life factor in commercial and pleasure vessels. Investing in energy-efficient solutions can lead to fuel cost savings of 10-30% over a vessel’s lifetime, a lighter environmental footprint, and compliance with international emissions standards.

Best Maintenance Practices for Marine Electrical Systems

Proper maintenance is crucial for vessel operators to ensure reliable performance and prevent costly breakdowns. Regular inspections of battery terminals for corrosion and the tightness of electrical connections are essential. Monthly backup power source testing, waterproof heat shrink and dielectric grease, and replacing chafed or discolored wiring are also recommended. Maintaining a written logbook, which records component changes, software updates, voltage readings, and abnormal behavior, aids in troubleshooting and provides proof of proactive upkeep for insurance or regulatory inspections.

New Developments to Watch in Marine Electrical Technology

Marine electrical systems are undergoing rapid innovation, with new low-weight, high-capacity lithium-ion batteries reducing installation footprints and service needs. Digital distribution panels replace traditional wiring looms, offering simpler diagnostics and user-friendly interfaces. The future will see more integration of renewable energy, including wind, solar, and fuel cells, orchestrated by smart controllers. Artificial intelligence can analyze historical system performance and forecast potential issues, allowing for just-in-time part replacements and reduced unscheduled downtime.