Table of Contents

Enclosure manufacturers play a crucial role in safeguarding electrical components across various industries. By providing robust and reliable enclosures, these manufacturers ensure the safety and optimal performance of electrical systems. Whether in energy, automotive, or manufacturing sectors, the significance of well-crafted enclosures cannot be overstated.

Understanding Enclosure Manufacturing

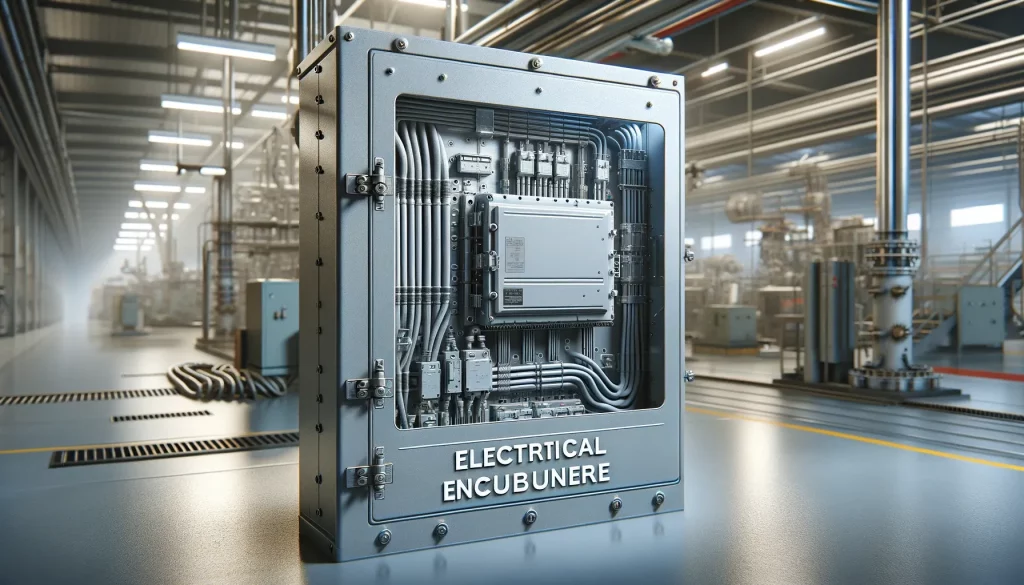

Electrical enclosures serve as the first line of defense, protecting critical electrical components from environmental hazards and human interference. They come in various materials, such as molded plastic and aluminum, each offering unique benefits. A well-designed Electrical enclosure not only ensures safety but also enhances the performance and longevity of the electrical components it houses.

Types of Enclosures and Their Applications

Enclosure types range from simple boxes to complex, custom-designed structures. They cater to diverse applications, including power distribution, industrial controls, and renewable energy systems. Each type is tailored to specific industry requirements, providing solutions for everything from basic protection to advanced features like waterproofing and thermal management.

Top Enclosure Manufacturers in the USA

The USA boasts several leading enclosure manufacturers, each with its specialties and product offerings. Companies like OKW Enclosures and Metcase are renowned for their high-quality products and custom solutions. Selecting the right manufacturer is crucial for obtaining enclosures that meet specific industry needs and standards.

Industry Standards and Compliance

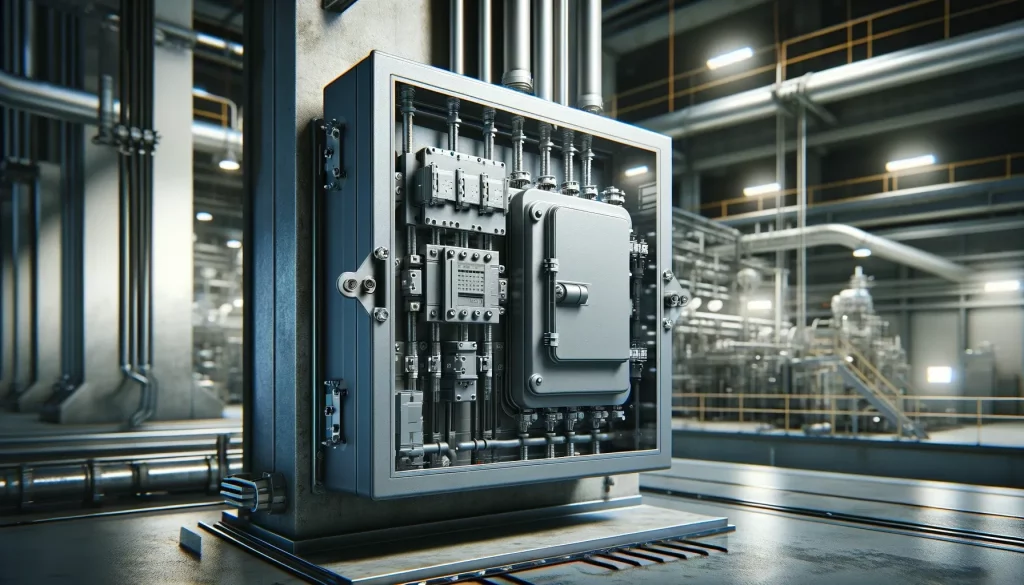

Compliance with industry standards, such as those set by the National Electrical Manufacturers Association (NEMA), is non-negotiable in enclosure manufacturing. These standards ensure that enclosures can withstand the conditions they’re designed for, whether it’s indoor, non-corrosive environments, or harsh outdoor settings.

Market Trends and Future Outlook

The enclosure manufacturing industry is evolving, with trends pointing towards increased use in renewable energy sectors and automation. The market is expected to grow significantly, driven by global energy consumption and technological advancements. This growth signifies a shift towards more energy-efficient and automated solutions in the industry.

Choosing the Right Enclosure Manufacturer

Choosing a manufacturer isn’t just about the product; it’s about reliability and adherence to standards. Look for manufacturers who can verify their claims and offer a range of solutions tailored to your specific needs. Great post read about the SD-WAN.

Innovative Practices in Enclosure Manufacturing

The industry is seeing innovative strides in manufacturing processes, with a focus on customization and advanced material use. Manufacturers like Rockett, Inc., pride themselves on offering a variety of materials and configurations, ensuring that each enclosure meets the specific requirements of the application.

FAQs

What are electrical enclosures and why are they important?

Electrical enclosures house and protect electrical components, ensuring safety and performance.

How do I choose the right enclosure material?

Consider your application’s environmental conditions and the specific requirements of your electrical components.

What standards should enclosure manufacturers adhere to?

Manufacturers should adhere to standards such as those set by NEMA for quality assurance.

Final Thought

Enclosure manufacturers are pivotal in ensuring the safety and efficiency of electrical components in various industries. As the industry evolves, staying informed about trends and advancements becomes increasingly important for making the best choices for your electrical needs.