Table of Contents

Reshaping UK Logistics is no longer a concept for the future. It is a present-day operational reality across transport, warehousing, and supply chains. As of 12 January 2026, UK logistics contributes £185 billion annually to the economy and employs over 2.8 million people. Digital transformation now underpins efficiency, compliance, and resilience across this sector.

Artificial intelligence and the Internet of Things are driving measurable gains in visibility, safety, and cost control. We see pressure from rising fuel costs, stricter emissions rules, and tighter delivery windows. UK operators must meet DVSA compliance, HMRC customs requirements, and ESG reporting expectations.

Technology now bridges these demands with operational clarity. AI improves decision-making speed. IoT delivers real-time asset intelligence. Together, they reduce waste and protect margins.

The Role of AI in Reshaping UK Logistics Operations

Artificial intelligence is changing how UK logistics businesses plan, predict, and perform. AI adoption accelerated after 2023 due to labour shortages and rising operational costs. According to industry data, 42 percent of UK logistics firms used AI-driven tools by Q4 2025. This shift directly supports productivity, compliance, and service reliability.

AI systems process large operational datasets quickly. They identify inefficiencies humans miss. UK fleets now use AI for route planning, fuel optimisation, and driver behaviour monitoring. These systems reduce empty miles and support compliance with the Road Traffic Act. As regulations tighten, AI ensures decisions remain data-backed and auditable.

AI-Powered Demand Forecasting and Inventory Accuracy

Demand forecasting accuracy matters in a market with volatile consumer behaviour. AI analyses historical sales, seasonal trends, and economic indicators. UK warehouses using AI forecasting reported inventory accuracy improvements from 89 percent to 97 percent in 2025. This directly reduced stockouts and overstocks.

Better forecasting also supports customs and VAT planning. Accurate volumes simplify HMRC declarations under the UK Border Operating Model. AI systems flag anomalies early, reducing penalties and delays. These tools integrate with ERP platforms already common in UK logistics operations.

AI in Transport Optimisation and Fleet Compliance

Fleet efficiency directly impacts margins and emissions reporting. AI route optimisation reduced average fuel consumption by 12.4 percent across UK fleets in 2025. These reductions support compliance with the UK Net Zero Strategy and Clean Air Zone charges.

AI systems also automatically monitor driver hours. They ensure compliance with the Working Time Directive and DVSA audit readiness. Real-time alerts prevent infringements before they occur. This reduces fines and reputational risk.

IoT as a Foundation for Real-Time Logistics Visibility

IoT technology delivers continuous asset intelligence. Sensors track vehicles, pallets, temperatures, and warehouse conditions. By January 2026, 58 percent of UK logistics operators used IoT devices at scale. This adoption supports transparency and service reliability.

IoT data feeds compliance reporting automatically. Temperature logs support Food Standards Agency requirements. Location tracking supports security and insurance standards. These systems reduce disputes and claims by providing verified evidence.

Warehouse Automation and Smart Asset Monitoring

Smart warehouses rely on IoT-enabled automation. Sensors monitor racking loads, conveyor performance, and energy usage. UK operators adopting IoT automation reduced picking errors by 34 percent in 2025. This directly improved customer satisfaction.

Energy monitoring also supports ESOS Phase 4 compliance. Automated data collection simplifies reporting and reduces audit preparation time. These efficiencies matter as energy prices remain volatile across the UK.

Cold Chain Integrity and Regulatory Assurance

Cold chain logistics face strict UK regulations. Medicines and food require precise temperature control. IoT sensors now monitor conditions every 30 seconds. In 2025, cold chain losses fell by 21 percent among UK adopters.

These systems support MHRA and FSA audits with timestamped data. Alerts trigger corrective action before spoilage occurs. This protects public safety and commercial value.

AI and IoT Integration Across UK Supply Chains

True transformation occurs when AI and IoT work together. IoT provides real-time data. AI converts it into actionable insight. This integration is Reshaping UK Logistics end-to-end.

For example, sensor data feeds AI models predicting vehicle maintenance needs. UK fleets using predictive maintenance reduced breakdowns by 18 percent in 2025. This improved delivery reliability and reduced roadside safety incidents.

Integration also supports supply chain resilience. AI models adjust plans instantly when IoT signals disruptions. This agility matters amid port congestion and weather volatility.

Regulatory Alignment Through Digital Systems

UK logistics regulation is becoming data-driven. Digital systems simplify compliance across agencies. AI automates reporting for emissions, driver hours, and customs declarations. IoT provides verifiable data trails.

From January 2026, HMRC increased penalties for inaccurate customs data. Digital accuracy now reduces financial risk. Systems aligned with CDS and GVMS platforms ensure smoother border movements.

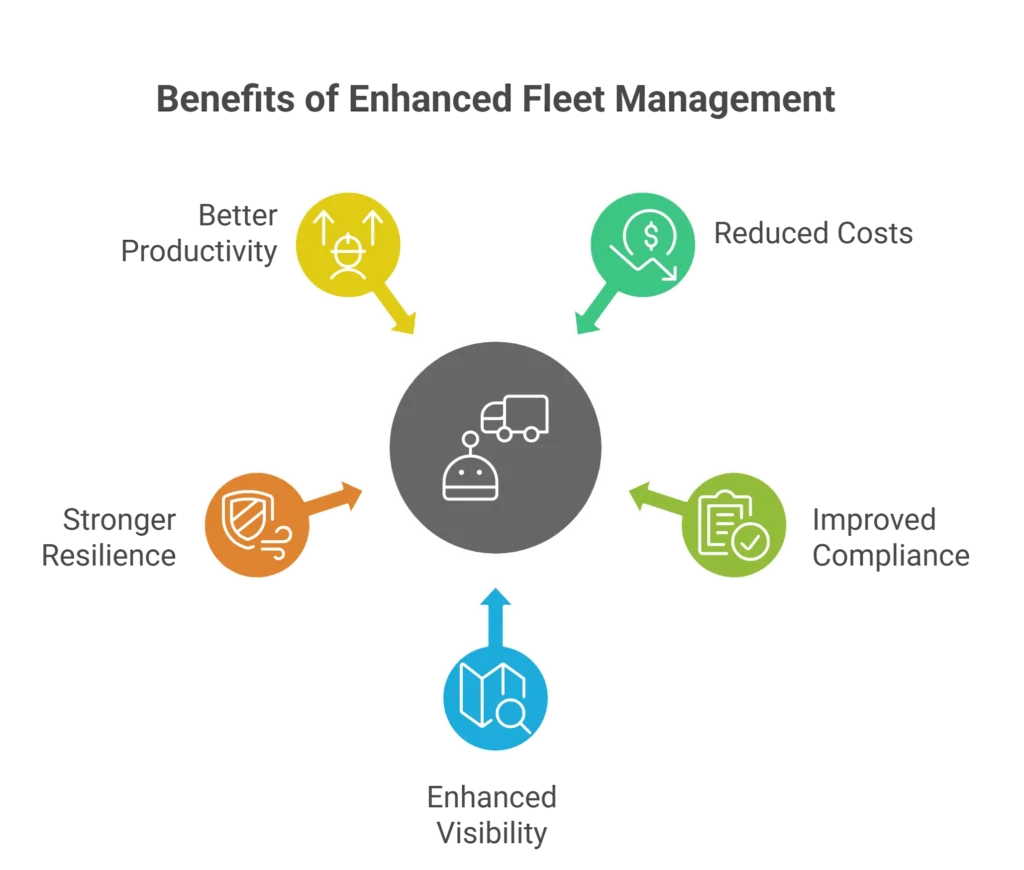

Key Benefits of Digital Transformation in UK Logistics

Digital adoption delivers consistent operational advantages. These benefits are measurable and regulation-friendly.

Key benefits include:

- Reduced operating costs through predictive planning and automation.

- Improved compliance with DVSA, HMRC, and environmental regulations.

- Enhanced customer visibility and service reliability.

- Stronger resilience against supply chain disruptions.

- Better workforce productivity and safety outcomes.

Technology Impact Comparison Table

| Area | Traditional Approach | AI and IoT Enabled Outcome |

|---|---|---|

| Route Planning | Manual and static | Real-time optimisation with 12.4% fuel savings |

| Inventory Accuracy | 85–90% average | 97% accuracy using AI forecasting |

| Cold Chain Monitoring | Periodic checks | Continuous monitoring every 30 seconds |

| Compliance Reporting | Manual audits | Automated, real-time data trails |

| Fleet Maintenance | Reactive repairs | 18% fewer breakdowns via prediction |

Bottom Line

Reshaping UK Logistics through AI and IoT is now essential, not optional. UK operators face tighter margins, stricter regulations, and higher customer expectations. Digital systems provide clarity, speed, and control across these pressures. AI improves decisions. IoT delivers verified data. Together, they reduce risk and unlock efficiency.

As of January 2026, regulatory compliance increasingly depends on digital accuracy. Businesses delaying transformation risk penalties and lost competitiveness. The most successful operators invest with clear goals, regulatory alignment, and workforce training.

FAQs

What is driving digital transformation in UK logistics?

Rising costs, labour shortages, stricter regulations, and customer expectations drive adoption.

How does AI help with UK compliance?

AI automates reporting and prevents breaches of driver hours and emissions rules.

Is IoT mandatory for cold chain logistics?

It is not mandatory, but strongly supports MHRA and FSA compliance.

Are small UK operators adopting AI and IoT?

Yes, cloud platforms reduced costs, enabling SME adoption since 2024.

Does digitalisation reduce logistics jobs?

It shifts roles toward higher-skilled positions rather than reducing overall employment.

Disclaimer

This article is for informational purposes only. It does not constitute legal, regulatory, or operational advice for logistics businesses.