Table of Contents

Logistics is transforming at a pace in 2025 and 2026, with automation driving measurable efficiency gains. The global logistics automation market is projected to grow from USD 73.37 billion in 2025, reflecting a 10.2% compound annual growth rate (CAGR) from 2024, and is forecast to reach USD 123.37 billion by 2029. We define logistics as the strategic movement, storage, and delivery of goods from origin to destination. Automation now underpins route optimisation, warehouse operations, transport scheduling, and last-mile delivery.

Early adopters report concrete results: companies using automation cut operational costs by 20% while reducing cycle times, often by as much as 50% in freight processing. Leading firms integrate robotics, AI, and real-time tracking to improve accuracy, speed, and transparency. The impact of automation extends beyond cost savings. It enhances reliability, customer satisfaction, and business scalability.

In transport and delivery, automation accelerates decision-making and reduces human error across planning, dispatching, and execution. Every logistical node, from smart ports to autonomous trucking systems, now benefits from data-driven workflows. The evidence confirms that automation is no longer optional; it is central to competitive logistics operations in 2025 and beyond.

The Logistics Automation Market: Growth and Drivers

The logistics automation market is expanding rapidly as demand for speed and efficiency grows. According to recent industry forecasts, the market will grow from USD 66.59 billion in 2024 to USD 73.37 billion in 2025 at a 10.2% CAGR, and it is expected to hit USD 123.37 billion by 2029. This growth is driven by e-commerce expansion, rising customer expectations for fast delivery, and cost pressures.

Across regions, automation adoption is uneven but accelerating. Asia-Pacific continues to register strong demand for automated systems, while Europe retains a significant share due to advanced logistics infrastructures.

In transport and delivery, automation technologies like autonomous route planning and telematics reduce delays and fuel consumption. Companies that leverage these systems gain a clear competitive edge through faster transit times and lower costs. The market trends confirm that automation will be a defining feature of modern logistics strategy.

Key Growth Drivers and Takeaways

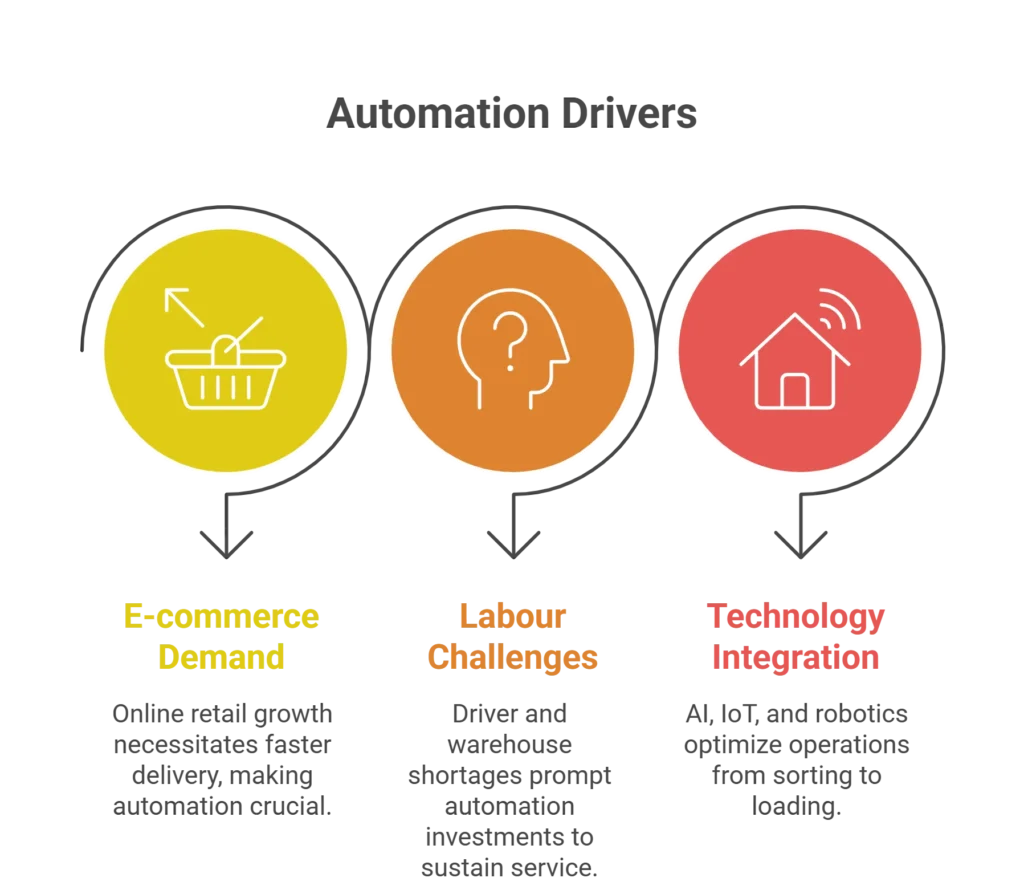

- E-commerce Demand: Rising online retail volumes increase the need for rapid delivery, making automation essential rather than optional.

- Labour Challenges: Persistent driver and warehouse labour shortages push firms to invest in automated systems to maintain service levels.

- Technology Integration: Artificial intelligence (AI), Internet of Things (IoT), and robotics streamline operations from sorting to loading.

How Automation Optimises Transport Operations

Route Optimisation and Fleet Management

Automation dramatically improves transport logistics through data-centric route planning and fleet control. Advanced systems use algorithms to reduce miles travelled, fuel usage, and delivery times. Automated route optimisation platforms can cut travel distances by 15%, reduce time inefficiencies by 20%, and lower energy consumption by 10% in simulated environments.

These systems integrate real-time traffic data, vehicle status, and delivery windows to ensure that drivers follow the most efficient paths. Automated fleet management also enables predictive maintenance, reducing breakdowns and unplanned downtime.

The result is a more reliable delivery network. Transport teams can plan with foresight rather than react to disruptions. For logistics professionals, this means predictable costs and improved delivery performance.

Table: Transport Automation Metrics

| Metric | Impact from Automation | Source |

|---|---|---|

| Market Size (2025) | USD 73.37 billion | turn0search19 |

| Route Distance Reduction | 15% | turn0academia21 |

| Time Efficiency Gain | 20% | turn0academia21 |

| Energy Consumption Drop | 10% | turn0academia21 |

| Operational Cost Savings | 20% reduction | turn0search4 |

These results demonstrate that automation delivers measurable improvements across key transport metrics. Firms that integrate automation can control costs and improve punctuality.

Warehouse Automation and Delivery Speed

Robotics and Automated Systems

Automation in warehousing is a major contributor to logistics efficiency. Robotics, conveyor systems, and automated guided vehicles (AGVs) handle repetitive tasks faster and with fewer errors than manual labour. Leading logistics companies deploy automation to streamline picking, sorting, and packing processes, reducing order fulfilment costs.

Automation also enhances real-time inventory visibility. Automated tracking systems update stock levels instantly, reducing overstock and stockouts. This accuracy feeds into faster delivery cycles and better customer service.

Integrating warehouse automation with delivery planning ensures that transport operations begin with accurate, ready-to-ship inventories. The end-to-end view reduces delays and maximises throughput without sacrificing quality.

Real-Time Tracking and Customer Expectations

Automated systems also support real-time shipment tracking. End customers receive up-to-minute updates, enhancing their experience and reducing call centre costs. Modern logistics providers use tracking dashboards that improve transparency at every stage of delivery.

For delivery teams, this visibility aids responsiveness. If unexpected delays occur, teams can adjust plans quickly, improving overall service reliability.

Last-Mile Delivery: Innovation and Challenges

Autonomous Vehicles and Drones

Last-mile delivery is the most costly and time-intensive segment of logistics. Innovations such as autonomous vehicles and drone delivery platforms are emerging to meet these costs. Integrated bus-drone delivery approaches can deliver parcels more efficiently while reducing total operational costs by over 6% compared to sequential planning.

However, it can try to solve the problem by custom software development that will enable it to automate its operations according to and in line with its actual operational requirements.

These systems also reduce carbon emissions and congestion in urban areas. While fully autonomous delivery vehicles are not yet widespread, pilot programmes demonstrate potential for rapid adoption.

Smart Infrastructure and Urban Logistics

Smart delivery corridors, based on IoT and data analytics, also improve last-mile success. Automation tools schedule deliveries during low-traffic periods and adjust routes dynamically based on weather, traffic, and delivery windows. This reduces failed delivery attempts and improves customer satisfaction in dense urban markets. Learn more in our article on Can You Really Trust AI in Logistics Without Risk?

Bottom Line

In 2025, automation is the key driver of efficiency in logistics, transport, and delivery. Data shows that the logistics automation market is growing rapidly, with the sector on track to exceed USD 123 billion by 2029. Automation accelerates route planning, cuts operational costs by approximately 20%, and improves delivery reliability. Successful logistics firms combine robotics, real-time tracking, and advanced analytics to reduce errors and improve customer experience. Investing in automation is now a strategic imperative for any logistics operation focused on competitive performance in today’s market.

Disclaimer:

This article is for informational purposes only and reflects market data and trends as of 2025.