Table of Contents

Industrial Packaging Automation is transforming how logistics and manufacturing handle materials. Today, in 2025, the packaging automation market is valued at around USD 81.09 billion and expected to reach USD 167.13 billion by 2035 with a 7.5% CAGR.

This growth reflects a clear industry shift toward automated systems that cut labour costs, improve throughput and simplify material handling workflows. In logistics, material handling accounts for a large portion of operational expenditure. Reducing these costs without sacrificing accuracy or speed is critical as global supply chains face labour shortages and rising wage pressures.

Industrial Packaging Automation brings speed, precision and consistency to packaging lines. Automated systems run continuously, cutting reliance on manual labour and reducing repetitive handling steps. This delivers measurable savings in labour, time and packaging materials. It also supports wider supply chain goals, including faster fulfilment and improved occupational safety.

Logistics leaders increasingly see packaging automation not as a technical add‑on but as a core strategy for reducing material handling expenses. In this article, we’ll explain how automation lowers costs, drives efficiency and strengthens operational resilience.

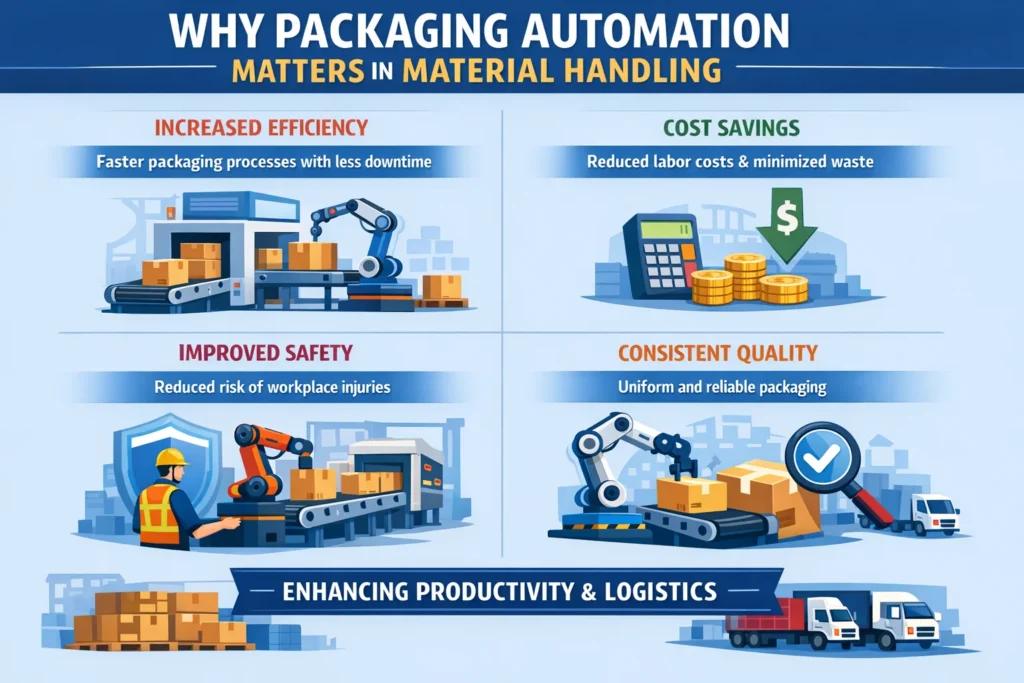

Why Packaging Automation Matters in Material Handling

Industrial Packaging Automation reshapes workflows at the point where products move from production to distribution. Manual packaging tasks require workers to lift, sort and secure products repeatedly. These tasks are physically intensive, slow and prone to error. Automated equipment such as robotic packers, conveyors and sealers performs these tasks with higher consistency. This reduces the time products spend in handling steps, leading to increased throughput without expanding labour costs.

Recent industry sources show that automated packaging systems can increase throughput by up to 30% compared to manual processes. This means facilities can process more units in less time, directly reducing the cost per packaged item. Higher throughput also smooths material flow through warehouses, preventing bottlenecks during peak demand.

Industrial Packaging Automation also cuts material waste. Machines apply packaging materials more precisely than human workers, lowering overuse and reducing scrap rates. Accurate packaging control leads to fewer damaged products in transit and fewer returns. These gains drive down total material handling costs and support better service levels.

Measurable Cost Savings From Automation

Industrial Packaging Automation delivers savings across several cost categories. Here are the main areas where automation impacts costs:

Here is the information in a simple table format:

| Cost Category | Impact of Automation | Typical Savings |

|---|---|---|

| Labour Costs | Reduces the need for manual handling tasks | Up to 50–60% reduction in labour expenses |

| Throughput & Productivity | Continuous operation increases output | 30%+ throughput gains |

| Material Waste | Precision reduces overuse of packaging materials | Lower scrap and defect rates — industry reports |

| Error & Rework Costs | Fewer packaging mistakes and damage | Up to 50% fewer errors |

These figures show how packaging automation lowers variable costs and improves fixed asset utilisation. Reducing manual labour translates into lower wage bills and fewer delays from absenteeism or fatigue. Higher accuracy means less rework, fewer material replacements and fewer costly returns.

How Automation Reduces Material Handling Steps

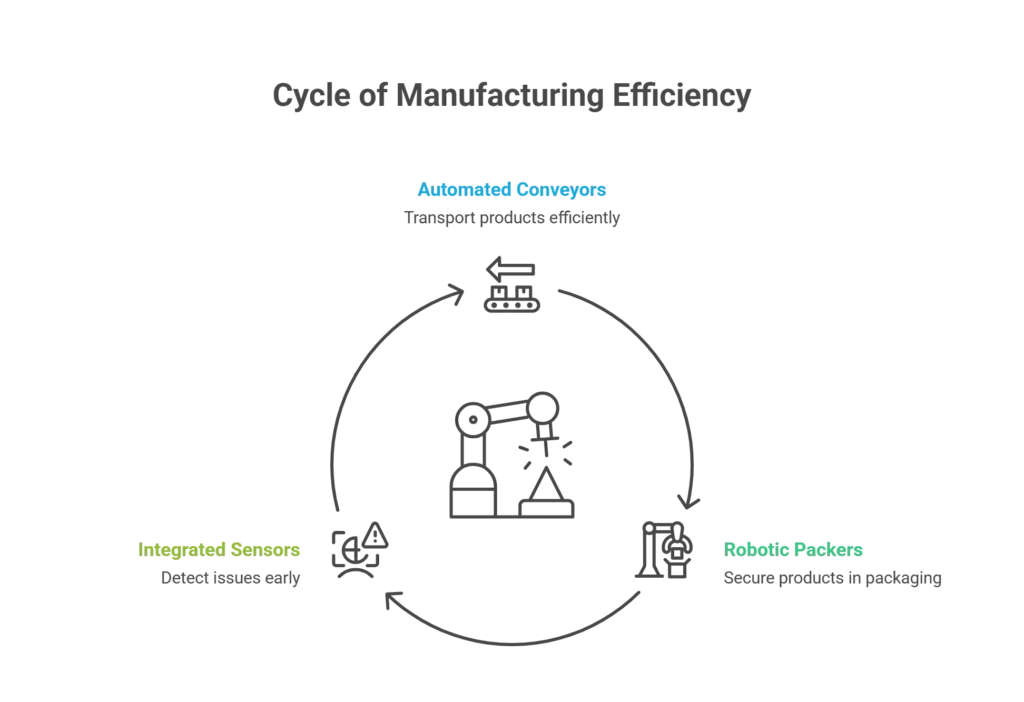

Industrial Packaging Automation simplifies material handling by integrating packaging into broader logistics systems. Automated conveyors, sorters and robotic arms reduce the number of times products are touched manually. Every touchpoint removed from the handling process lowers cost and risk. For example:

- Automated conveyors transport products without manual lifting.

- Robotic packers secure products in correct packaging formats every time.

- Integrated sensors detect issues early, reducing stoppages.

Streamlining these steps also improves safety. Fewer manual interventions mean fewer opportunities for workplace injuries, which are costly in terms of compensation and lost productivity. Automation supports ergonomic design, directing human labour toward value‑added tasks rather than repetitive handling.

Industrial Packaging Automation in Modern Warehouses

Modern warehouses link packaging automation with material handling technology. Warehouse management systems (WMS) and automated material handling equipment work together to reduce operational friction. When packaging lines communicate with inventory systems, materials move more predictably and efficiently through the facility. Automated systems also improve data visibility, allowing managers to forecast demand and plan material flows more accurately.

The global automated material handling equipment market is expected to grow from USD 72.61 billion in 2025 to USD 170.64 billion by 2034. This growth highlights how logistics and supply chain operators are investing in tools that move products faster, safer and at lower costs. As packaging automation integrates with these systems, material handling costs drop through reduced labour dependency, better space utilisation and improved scheduling.

Case: Real‑World Impact on Material Handling

Consider a third‑party logistics facility that integrates industrial packaging robots with its sorting and fulfilment operations. Before automation, workers manually packed and sealed pallets, walking between stations and slowing the line. With automation, these tasks are consolidated into continuous flow systems. Packaging robots wrap pallets with exact tension and speed, reducing pallet damage and preventing delays. A connected WMS schedules packaging based on incoming order batches, smoothing demand peaks.

Operators in the facility saw a 40–50% drop in labour hours associated with packaging and a noticeable decline in handling errors within months of implementation. Costs associated with product damage also reduced significantly. These results reflect broader industry patterns where automation improves performance while lowering costs. Don’t miss our recent post about Standard Pallet Weight: How Much Does a Pallet Weight?

Choosing the Right Packaging Automation Strategy

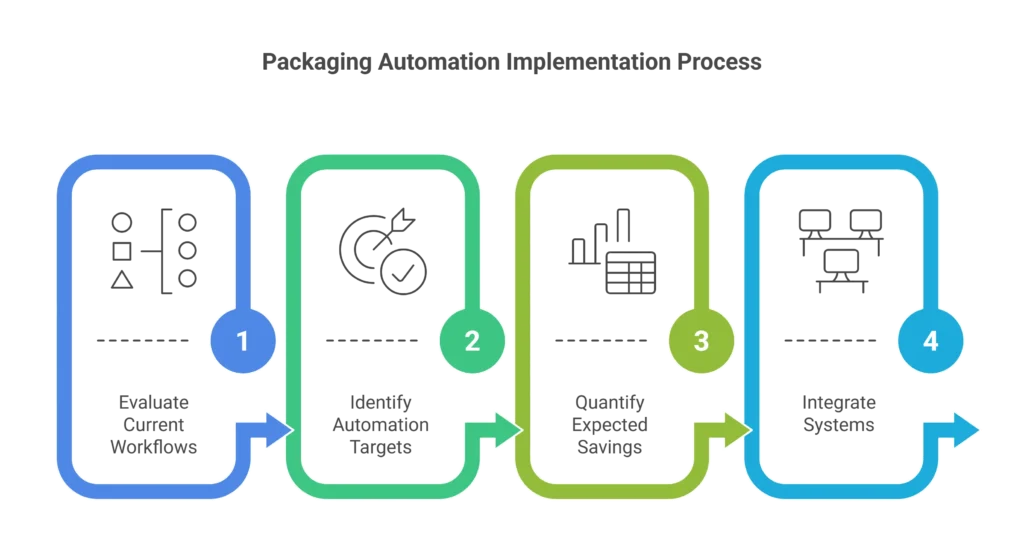

Selecting the right automation solution depends on volume, product type and long‑term strategy. Here are key steps logistics teams should follow:

- Evaluate current workflows. Map all material handling and packaging tasks.

- Identify automation targets. Prioritise repetitive, labour‑intensive steps.

- Quantify expected savings. Use metrics like labour hours per unit and error rates.

- Integrate systems. Ensure packaging automation links with WMS and order systems.

A successful automation plan should balance upfront costs with projected savings. Automation may require capital investment, but the reductions in labour and material waste typically deliver payback within a few years.

Bottom Line

Industrial Packaging Automation is essential for cutting material handling costs in 2025 logistics operations. By reducing labour dependency, increasing throughput and minimising errors, automated systems lower operational expenses without sacrificing quality. Logistics and manufacturing leaders can use data from packaging automation to plan smarter workflows, improve service levels and control costs. A structured approach to adopting these technologies ensures measurable returns and stronger long‑term performance. For reliable benchmarks and growing trends, authoritative resources like Fortune Business Insights and market research on packaging automation offer useful insights.

Disclaimer:

The savings and impacts mentioned are based on industry reports and may vary depending on specific circumstances, systems, and operational factors. Actual results may differ.